By Glenn Stehle, an engineer who began working in the oil industry in 1974. After a two-year stint with Cities Service Oil Company, he worked for two years for Henry Engineering, a petroleum engineering consulting firm. Upon leaving Henry Engineering he worked as an independent engineering consultant in all facets of the oil and gas business. He has extensive experience in drilling operations. He retired in 2000 and now lives in Mexico.

Yves asked me to take a look at a recent New York Times story to see if it contained any information that might provide a clue as to what caused the blowout on the Deepwater Horizon. This is a pretty treacherous exercise because information, and especially the sort of detailed information that is needed, comes from firsthand witnesses who were present at the wellsite. The NY Times story actually had some of that sort of information, so let me take a look and try to make some sense of it.

By far the most important piece of information the NY Times provides is this:

As the job unfolded, however, the workers did have intermittent trouble with pockets of natural gas. Highly flammable, the gas was forcing its way up the drilling pipes.

As a well is being drilled through a gas-bearing formation, there is always a release of gas. This is the gas that is contained in the formation rock that is being cut away. But the quantities are small. And the amounts of gas the drilling crews of the Deepwater Horizon were encountering were anything but small, as the NY Times goes on to explain:

At one point during the previous several weeks, so much of it came belching up to the surface that a loudspeaker announcement called for a halt to all “hot work,” meaning any smoking, welding, cooking or any other use of fire.

What this indicates is that they were drilling underbalanced. Let me try to explain.

But first, a little lesson in physics is in order.

The pressure exerted by a column of liquid of height h and density ρ is given by the hydrostatic pressure equation p = ρgh.

The photo in this Wikipedia link may help to visualize what this means. For the apparatus in the photo to be in equilibrium, the pressure exerted by the gas trapped in the horizontal glass tube at the bottom must be equal to the hydrostatic pressure exerted by the hydraulic column contained in the vertical tube on the far left. The hydrostatic pressure exerted by that vertical column on the left is a function of its 1) height and 2) the density of the fluid that composes it.

If the vertical column is not of sufficient height and density, the hydrostatic pressure will be too low, the gas trapped in the horizontal tube will expand and the vertical column of fluid in the tube on the left will be ejected out the top. Thus we would have a “blowout,” that is unless we have a valve at the top of the vertical tube on the left that we can shut, thus preventing such an occurrence.

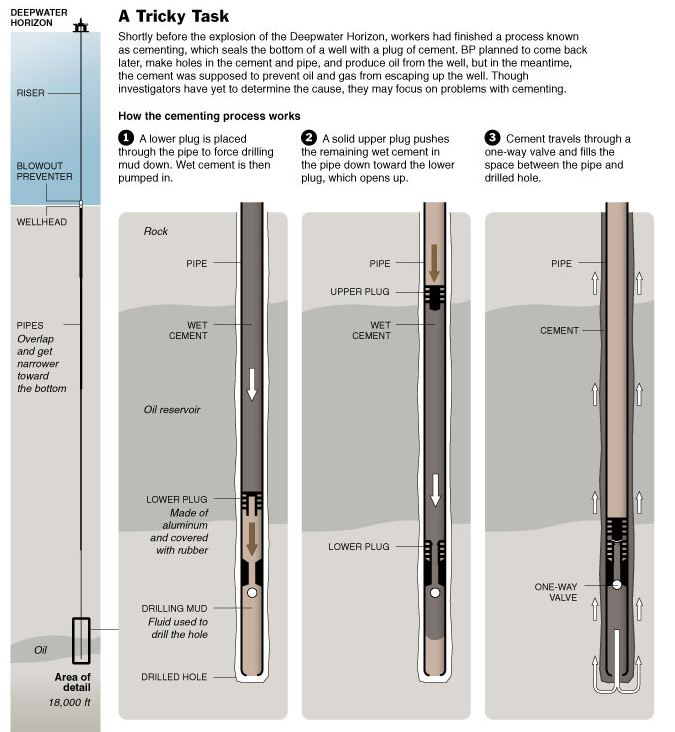

Of course this is a highly simplified visualization. Oil and gas reservoirs are not small empty horizontal tubes, but vast formations composed of rock of various porosities and permeabilities, and the vertical fluid column rises directly above the reservoir. For a better visualization, take a look at the illustration from the NY Times article (click to enlarge, or try the link):

Looking at the drawing on the far left, imagine the oil and gas reservoir labeled “oil” in the drawing as being the horizontal glass tube in the Wikipedia photo. Imagine the liquid contained in the wellbore and riser (the vertical column between the “oil” reservoir and the Deepwater Horizon) as being the fluid column in the far left vertical tube from the Wikipedia photo. If the hydrostatic pressure exerted by the fluid column in the riser and wellbore is equal to the pore pressure exerted by the oil and gas in the reservoir, then the system is in balance. No oil or gas will flow from the reservoir into the wellbore. However, if the hydrostatic pressure exerted by the fluid column in the riser and wellbore is less than the pressure exerted by the reservoir, then oil and gas will flow into the wellbore. Thus you have a “blowout,” unless you have a valve (Blowout preventer) somewhere in the vertical column that you can close to prevent that from happening.

The ideal situation is to have the hydrostatic pressure exerted by the vertical fluid column (between the Deepwater Horizon and the “oil” reservoir) slightly greater than the pressure exerted by the “oil” reservoir. This assures that no oil or gas will enter the wellbore. A caveat: The hydrostatic pressure exerted by the fluid column cannot be too great, or the drilling fluid can flow from the wellbore into the “oil” reservoir, a situation that in industry jargon is called “losing circulation.”

The fact that, as reported in the NY Times story, “gas was forcing its way up the drilling pipes” as “the job unfolded” indicates the situation was not ideal. In order for gas to enter the wellbore, the hydrostatic pressure exerted by the vertical fluid column (between the Deepwater Horizon and the “oil” reservoir) would have to be less than the pressure exerted by the “oil” reservoir. This situation in industry jargon is called “drilling underbalanced.”

Since the vertical distance between the Deepwater Horizon and the “oil” reservoir is a fixed height, the hydrostatic pressure exerted by the fluid column is adjusted by adjusting the density of the drilling fluid. Various fluids are used in drilling wells. Fresh water has a density of about 8 lbs/gallon. Concentrated brine has a density of about 10 lbs/gallon. Above this, density is achieved by adding solids to the drilling fluid, these drilling fluids in oilfield vernacular being known as “drilling mud” or just “mud.” Drilling mud can have a density up to 20 lb/gallon or more.

When it became evident that gas was entering the wellbore from the “oil” reservoir, the appropriate course of action would have been to raise the density of the drilling mud, thus preventing entry of gas into the wellbore. Drilling in an underbalanced situation is a bit risky, but for various reasons (for instance, you can make hole faster) it is sometimes done. To attempt to run casing under these circumstances, however, is suicidal.

Why the decision was made to attempt to run casing under these circumstances is not known. I can say that the time required to circulate and condition the drilling mud—-that is to raise its density or “mud weight”—-on a well of this depth could run into days. Perhaps there were incentives to cut corners.

The well did not blow out while running casing. But apparently gas did enter the wellbore during the cementing process. This creates a situation known in industry jargon as “channeling,” where the cement has vertical pathways running up and down through it. Imagine trying to lay a concrete slab with gas percolating up from below.

Typically, after the cement job is complete, and on a job of this importance, a “log” (sorry, more industry jargon) would be run to verify the integrity of the cement job. We of course do not know whether this was done or not. Again, this is an expensive and time consuming operation. Here’s a link to Schlumberger’s web page describing how these logs work and what they tell you.

So here’s a summary of, again with very limited facts but in my august opinion, what the situation was:

1) The cement (between the casing and the wellbore) that normally would have hardened and isolated the “oil” reservoir, thus preventing any gas or fluids from entering the wellbore, was “channeled.”

2) The fluid column above the cement (between the top of the cement and the Deepwater Horizon) that normally would have exerted sufficient hydrostatic pressure against the “oil” reservoir to prevent oil and gas from entering the wellbore was of insufficient density to do so.

3) This fluid column was also cut with gas. With time, this gas migrates upwards, small bubbles joining with other small bubbles as they bump into each other, forming larger and larger bubbles, closer and closer to the surface.

The NY Times reports that the following day “the crew was using seawater to flush drilling mud out of the pipes.” This is consistent with reports from NOLA.com (hat tip jdmckay):

An attorney representing a witness says oil giant BP and the owner of the drilling platform, Switzerland-based Transocean Ltd., started to remove a mud barrier…

(…)

In the case of the Deepwater Horizon, Scott Bickford, a lawyer for a rig worker who survived the explosions, said the mud was being extracted from the riser…“Suddenly, with explosive fury, water and mud came hurtling up the pipes and onto the deck, followed by the ominous hiss of natural gas,” The NY Times goes on to report. “In seconds, it touched some spark or flame.”

As a gas bubble nears the surface, it starts expanding as the hydrostatic column holding it down diminishes. So the return circulation grows stronger and stronger, but not “suddenly,” and not with “explosive fury.” There are warning signs before all hell breaks loose. So somebody was clearly asleep at the wheel. Perhaps this is where another bit of information provided by the NY Times story is important. The NY Times article indicates that there was a big party underway, with four BP executives in attendance. Perhaps nobody was minding the shop.

When the well started to unload this greatly diminished the hydrostatic head pressing down on the cement job. The faulty cement job might have held up against the reservoir pressure with the help of a full hydrostatic head, but the pressure differential was now too great, and indications are it gave way.

The last line of defense was the blowout preventers. We can only speculate as to why they didn’t close. But again there are all sorts of reasons, more than a few attributable to negligence or human error, which would explain why they didn’t.

Outstanding post. Thank you, Mr. Stehle.

Double that. Very interesting.

I second that!

It is always gratifying to have a post written by one of those who really know.

Thanks again.

”

post written by one of those who really know.

”

Truly difficult to know what is one mile deep into the ocean, let alone two more miles deep into the sea-bed. Are you guessing that there is a lava tube adjacent to the pocket of petroleum? Was lava heat the driving force that pushed the mild mannered liquefied natural gas up through the pipe? Did that LNG fail to expand-cool slowly because of the intense heat of the lava nearby? Did such intense heat both explode the gas etc. upward and ignite the gas as it reached the oxygen filled atmosphere? Is our global warming increasing the activity of lava in Iceland but also under GOM? It is now less than 2 years to the end of the Mayan Calendar. Are we marking off the days?

?

?

?

?

?

?

?

?

So Glenn, I’d read the article, but it’s desirable to have the kind of detailed parsing you’d provided. I’d read that prior, major gas release as a significant warning, but was in no position to know how the drill crew would assess and compensate for it.

You indicate that the fluid column would be cut with gas. Would this aggregating and expanding gas be sufficient to abruptly back out the diminishing mud volume by itself after a critical point? Certainly if the mud was cut and/or there was a progressive gas leak throught he channeled mud there should have been a pick up in circulation of the outflow that the crew should have noticed, _not_ an abrupt process, as you make plain. That is how I read the sequence of your description, though perhaps that is only my misapprehension of your analysis. Going over your description, a perhaps slightly different inception of the blowout suggests itself. Obviously the cement plug failed (oil coming up), and the dropping hydrostatic pressure as you describe seems the likely precipitant. A more recent story in Yves’ links (yesterday?) describes the blowout sequence as a) a massive ‘thump’ experience on the drillship, followed by 2) a lesser, longer, vibrating impact. My inference is that there was a catastrophic failure of the plug first, than a gas blowout. If there wasn’t a lot of gas in the mud, there may not have been enough of a rise in outflow for the rinse crew to really notice, though given the history of gas coming up one would think they’d be edgy on that. Then again, if they thought that the plug was good, they may have let down their guard.

It sure sounds like the cement plug was bad. It will come out when they review how/if the log run was performed.

My takeaway from the whole event is broader, though. “You drill, you spill,” goes the remark on this elsewhere ont he web, but that is the longstanding factual record of the industry. Whether spills/blowouts are less frequent than they used to be, they happen with sufficient frequency that they should be seen as inevitable. I remember clearly the Ixtoc disaster, but the oil industry has spread around enough smile gas that the American public does not; something that only happens to ‘furriners’ who don’t know how to make money at this game. Major ecological disasters are the inevitable stepchild of ocean drilling. I had that perspective when our ‘liberal’ president of the moment stepped forward to throw open the coastlines to Big Oil in a way that the former ‘convervative’ oil man president never succeeded in doing. We can talk all we want to about the culpability of BP, Transocean, and all the rest; it may be considerable, though it’s possible that simple human error will prove to the the primary cause of this event. It’s with our government and the executors thereof that, to me, the real blame lies. They are captive to the drill industry and it’s mentality (nothing personal, Glenn), and no stewards of the populace, the country, or the Earth. They drill, they spill, and that is the ONLY perspective to have when evaluating the worth and viability of any and all offshore extraction. A perception that this disaster was _inevitable_ (if not here, now, then thereabouts, anytime) really changes the calculus—only that perception, if it is achieved at all which I yet doubt, is now to late to avoid this particular experience.

After a long enough period of time—-days, months, years, who knows?—-the gas trapped in the annular space between the production casing and the open hole and riser would most likely work its way to the surface.

Yes, you read the sequence of my analysis correctly, “there should have been a pick up in circulation of the outflow that the crew should have noticed, _not_ an abrupt process.”

Any plugs would have been at least a mile beneath sea level, which implies at least a mile of drilling mud or seawater insulation between the drilling rig and them. Their giving way could not be heard on the drill ship.

Thanks for the very good summary of what probably occurred. Not the least bit surprising given BP’s history of ‘accidents’.

Excellent. Thank you.

Thanks DS for the clear and concise summary.

I’m interested in the concrete plug that Halliburton had just installed. Two things jump out: first that the cement for this plug was mixed with nitrogen to make it a sort of mousse, and second that Halliburton never installed the final cement plug at the top of the well (link below).

Does the fact that the cement was mixed with nitrogen gas (making it a “mousse”) make your theory of the cement channelling all the stronger since I assume that it is easier for the natural gas that was just below the plug to penetrate into the less dense cement mousse?

And does the fact that the final cement plug was never installed mean that there was a gap between the top of the cement plug and the blowout prevention valve? Wouldn’t this allow the cement plug to accelerate as it was blown out, rising with an ever increasing velocity until it met the blowout preventer and perhaps destroying it?

http://www.chron.com/disp/story.mpl/business/deepwaterhorizon/6990221.html

I think you’re confusing the primary cement job, which fills the annular space between the production casing and the open hole with cement, with the cement plugs, which are placed entirely within the production casing. There’s also a wood and rubber or metal and rubber plug that, after the cement is pumped during the primary cement drop, is dropped behind the cement to separate the fluid that is used to displace the cement from the cement itself (see illustrations from NY Times article). All these different plugs get a little confusing, no?

There would be no gaps. Keep in mind that these plugs are all located miles below sea level, with miles of heavy mud between them and the wellhead and blowout preventer (see the illustration from the NOLA.com article). Also keep in mind that the natural gas that would fill a 9’x9’ room with an 8 foot ceiling at atmospheric pressure would only occupy one cubic foot at 10,000 psi. So what begins as a little trickle 18,000 feet below the surface slowly grows to a screaming inferno as it nears the surface.

You ask: “Does the fact that the cement was mixed with nitrogen gas (making it a “mousse”) make your theory of the cement channelling all the stronger since I assume that it is easier for the natural gas that was just below the plug to penetrate into the less dense cement mousse?”

I don’t know, but I’m sure that, according to the Halliburton salesman, the new cement formulations are superior to the old ones in every way. And maybe they are!

Thanks for explanations, helpful.

From what I gather, seems that extracting mud prior to setting 2nd cement plug is contrary to best practices, no?

From the NOLA article:

“at least” 2 plugs. So 2 is minimum… no?

And “MMS requires”… as I understand, MMS requirements on this were non-existent, replaced by successful lobbying efforts rendering MMS edicts to “suggestions” w/industry left to implement as they see fit.

In fact, further down in that article:

… which suggests to me, again, that…

a) “2 plug min.” was only a suggestion

b) and that “2 plug min.” was established best practices

c) that BP (or platform management) made a decision to go w/1 plug, for some reason.

You said:

I haven’t seen an account whether this “log” was done either. Again, from NOLA article:

It goes on to say that “best practices” require redundant (backup) activation mechanism for BOP, and that first line activation is from some (presumably) electronic panel on drilling platform. So, platform personel….

a) tested 1st line BOP activation, it worked.

b) began displacing mud

c) methane bubble ignited on platform, explosions/fire etc.

I haven’t read whether anyone on platform actually tried to activate BOP after 1st explosion. Seems like there was confusion/panic, but did anyone at that time actually push the “Close the BOP” button?

How is that button connected to BOP? Is it wiring all the way down the pipe, or hydraulics, or radio control? I currently don’t envision whether initial explosion(s) would have broke mechanism on platform to activate BOP. I also haven’t seen explanation describing what a “backup BOP activation” mechanism looks like… eg. is it supposed to be another system entirely?

…

I’ve read in some detail the capabilities, design etc. of that drilling platform. Seems it was (and I emphasize “was”) most sophisticated such device in the world. Personally, I’m impressed by that thing (I did not know how these worked, how they were used/designed until this event). It also seems to me this platform was perfectly capable of executing/completing this well in “best practices” methodology, and that the methodology was well established. I also gather that this particular well was less demanding technically than a number of others that had been done successfully.

Right now, this looks to me like human error somewhere w/in domains of…

a) omitting operations (multiple plugs) for redundant blowout prevention

b) lack of attentiveness to monitor/evaluate/test work product/systems done very close to the end of what, by all observation, was very close to being a successful project.

The dearth of technical specificity from BP &/or Transocean detailing these procedures (or lack thereof) raises suspicion in my mind… makes me think whoever may have cheaped out of a few steps which led to explosions is doubling down for a major CYA legal quagmire. Among other things, seems like a court order to preserve all communications/work orders (or whatever communications may be documented) would be in order, if BP/Transocean/HB hasn’t already burned up their shredders.

Jdmckay,

I want to furnish the link to the NOLA.com article which accidentally got omitted from the post. It, like the NY Times, gives some eyewitness reports from people who were actually on the scene, plus it’s got some great graphics and illustrations.

http://www.nola.com/news/gulf-oil-spill/index.ssf/2010/05/safety_fluid_was_removed_befor.html

The authors are clearly not drilling professionals, because they get some parts muddled, but as far as reporters go, they do a superb job.

The authors cite several eye witnesses who claim they were circulating the drilling mud out of the riser when the blowout occurred. The question is of course: Is this true? If it is, then this means the blowout occurred from the annular space between the production casing and the riser, which supports my theory. It also means it is irrelevant whether they had set one plug, two plugs or ten plugs inside the production casing below the level of the seafloor. The blowout occurred outside the production casing. If, however, the blowout occurred between the annular space between the drill pipe and the production casing, this would discredit my theory. This means that the blowout occurred from within the production casing. For this to happen, the cement plug that follows the primary cement job failed, or the production casing collapsed or parted or developed a leak.

It’s important to keep in mind that there are probably only a couple of people on the planet who have all the facts about what was going on. This would be the Transocean toolpusher and the BP company man, and the latter only if he wasn’t MIA at the big BP shindig. (Could this be why BP is saying everything is Transocean’s fault, because they weren’t even around for all the action? How can you blame them if they weren’t even there, right?) All other witnesses have a incomplete fact sets.

And needless to say, BP’s company man is not talking. I’ll bet they’ve got him as bottled up as Goldman Sachs has Fabulous Fab. As the NOLA.com authors observe: “BP spokesmen have declined to confirm or deny these descriptions of events, saying the details will come out as a result of the ongoing investigation.”

My experience has been that, for every casing failure or cement plug failure, there are probably ten primary cement job failures. The annular space between the production casing and the open wellbore is a far less controlled environment than that inside the confines of steel pipe. So I’m going with the odds here. Plus, as I indicated in my original post, eyewitness accounts give pretty convincing testimony that they BP was operating underbalanced. So the scenario I constructed is the one where I believe all the pieces of the puzzle fit together the best. Of course I’m missing many piezes of the puzzle.

Thanks… real good discussion.

Yah, that’s kind’a bottom line.

I have a feeling it’s going to be a while before bottom line facts emerge as to cause, especially given extraordinary liability involved.

Reminds me… I recall seeing news in last +/- 18 mos. that Exxon is still litigating awarded damages in Valdez incident. And Enron is till in court trying to enforce contracts signed as result of their faux “California Energy Shortage.”

Whatever corrections made in regulations, seems to me one that is needed: have all the drillers in gulf support one insurance pool that covers everything in such an event… everything. Then let insurers duke it out in court w/drilling (or any involved) company.

This was discussed over at the http://www.theoildrum.com. Here are some interesting posts on the subject from their forums (communications from employees/family of those on the rig that blewout).

Regards,

Cooter

COMM 1

> Terry xxxxxxx, who works for ADTI, had a son who was one of the BP Company reps on the Horizon when the incident occurred. Here’s what he sent me.

>

> TALKED TO MY SON, HE IS AT HOME NOW, AND IN GOOD SHAPE, WHAT I WAS TOLD WAS THEY HAD SET A 9-5/8 TAPERED PRODUCTION LINER, DID THEIR CEMENT JOB, HAD POSITIVE TESTED, AND ALSO NEGITIVE TESTED, THEY WERE GOING TO SET A BALANCED PLUG AROUND 3000′ BELOW THE WELL HEAD WHICH WOULD BE AT ABOUT 8000′, THE SENIOR COMPANY MAN WANTED TO SET THE BALANCED PLUG IN MUD, BUT THE ENGINEERS WANTED TO DISPLACE WITH WATER PRIOR TO SETTING BALANCED PLUG, SO THEY DISPLACED FROM 3000′ BELOW MUD LINE, AND WERE GETTING READY TO SET PLUG. THE DERRICKMAN CALLED THE DRILLER AND SAID HE NEEDED HELP, HE HAD MUD GOING EVERYWHERE, AND ABOUT THIS TIME THE DRILL FLOOR DISAPEARED, THEN THERE WAS AN EXPLOSION, THEN A SECOND EXPLOSION.

>

> THE FLAMES ARE NOW GOING STRAIGHT UP ALLOWING EVACUATION OF MEN, THEN YOU KNOW THE REST.

>

> THE HANDS THAT ARE MISSING ARE THE ONES THAT WERE ON THE DRILL FLOOR AND PUMP ROOM. YOU KNOW THE RESULTS OF THAT. THIS ALL TOOK PLACE IN LESS THAN A MINUTE.

>

> RIG WAS EVACUATED IN ABOUT 25 MINUTES.

>

> IT IS BELIVED THAT THE SEAL ASSEMBLY AT THE WELL HEAD GAVE UP. IF THAT IS THE CASE AND THEY WOULD HAVE SET THE BALANCED PLUG IN MUD THEN DISPLACED THE RISER, IT WOULD ONLY HAVE DELAYED WHAT HAPPENED BY A COUPLE OF HOURS.

>

> GAS MUST HAVE CHANNELLED THROUGH THE CEMENT JOB AND UP THE BACK SIDE OF THE 9-5/8 PRODUCTION CASING.

>

> THIS IS ALL I KNOW AT PRESENT.

COMM 2

I received the same info. Today I got a slightly different version but very similar which I’ve attached:

I continue getting calls asking what happened on this problem so here’s a response from a friend in the oil business with possible inside info on the blowout. Please keep in mind this is an “UNOFFICIAL” report so this may or may not be factual. However, the scenario as written makes reasonable sense as far as I am concerned. The focus needs to be on well control now and not speculation as to what may or may not have happened. BP, the MMS and most likely a third party will certainly provide a very in-depth investigation which will be the official report. Having said that I would certainly not look forward to a copy of that report as it will be furnished only to those in need due to the possible liabilities of the findings.

Details as conveyed to me:

This well had been giving some problems all the way down and was a big discovery. Big pressure, 16ppg+ mud weight. They ran a long string of 7″ production casing – not a liner, the confusion arising from the fact that all casing strings on a floating rig are run on drill pipe and hung off on the wellhead on the sea floor, like a “liner”. They cemented this casing with lightweight cement containing nitrogen because they were having lost circulation in between the well kicking all the way down.

The calculations and the execution of this kind of a cement job are complex, in order that you neither let the well flow from too little hydrostatic pressure nor break it down and lose the fluid and cement from too much hydrostatic. But you gotta believe BP had 8 or 10 of their best double and triple checking everything.

On the outside of the top joint of casing is a seal assembly – “packoff” – that sets inside the subsea wellhead and seals. This was set and tested to 10,000 psi, OK. Remember they are doing all this from the surface 5,000 feet away. The technology is fascinating, like going to the moon or fishing out the Russian sub, or killing all the fires in Kuwait in 14 months instead of 5 years. We never have had an accident like this before so hubris, the folie d’grandeur, sort of takes over. BP were the leaders in all this stretching the envelope all over the world in deep water.

This was the end of the well until testing was to begin at a later time, so a temporary “bridge plug” was run in on drill pipe to set somewhere near the top of the well below 5,000 ft. This is the second barrier, you always have to have 2, and the casing was the first one. It is not know if this was actually set or not. At the same time they took the 16+ ppg mud out of the riser and replaced it with sea water so that they could pull the riser, lay it down, and move off.

When they did this, they of course took away all the hydrostatic on the well. But this was OK, normal, since the well was plugged both on the inside with the casing and on the outside with the tested packoff. But something turned loose all of a sudden, and the conventional wisdom would be the packoff on the outside of the casing.

Gas and oil rushed up the riser; there was little wind, and a gas cloud got all over the rig. When the main inductions of the engines got a whiff, they ran away and exploded. Blew them right off the rig. This set everything on fire. A similar explosion in the mud pit / mud pump room blew the mud pumps overboard. Another in the mud sack storage room, sited most unfortunately right next to the living quarters, took out all the interior walls where everyone was hanging out having – I am not making this up – a party to celebrate 7 years of accident free work on this rig. 7 BP bigwigs were there visiting from town.

In this sense they were lucky that the only ones lost were the 9 rig crew on the rig floor and 2 mud engineers down on the pits. The furniture and walls trapped some and broke some bones but they all managed to get in the lifeboats with assistance from the others.

The safety shut ins on the BOP were tripped but it is not clear why they did not work. This system has 4 way redundancy; 2 separate hydraulic systems and 2 separate electric systems should be able to operate any of the functions on the stack. They are tested every 14 days, all of them. (there is also a stab on the stack so that an ROV can plug in and operate it, but now it is too late because things are damaged).

The well is flowing through the BOP stack, probably around the outside of the 7″ casing. As reported elsewhere, none of the “rams”, those being the valves that are suppose to close around the drill pipe and / or shear it right in two and seal on the open hole, are sealing. Up the riser and out some holes in it where it is kinked. A little is coming out of the drill pipe too which is sticking out of the top of the riser and laid out on the ocean floor. The volumes as reported by the media are not correct but who knows exactly how much is coming?

2 relief wells will be drilled but it will take at least 60 days to kill it that way. There is a “deep sea intervention vessel” on the way, I don’t know if that means a submarine or not, one would think this is too deep for subs, and it will have special cutting tools to try to cut off the very bottom of the riser on top of the BOP. The area is remarkably free from debris. The rig “Enterprise” is standing by with another BOP stack and a special connector to set down on top of the original one and then close. You saw this sort of thing in Red Adair movies and in Kuwait, a new stack dangling from a crane is just dropped down on the well after all the junk is removed. But that is not 5,000 ft underwater.

One unknown is if they get a new stack on it and close it, will the bitch broach around the outside of all the casing??

In order for a disaster of this magnitude to happen, more than one thing has to go wrong, or fail. First, a shitty cement job. The wellhead packoff / seal assembly, while designed to hold the pressure, is just a backup. And finally, the ability to close the well in with the BOP somehow went away.

A bad deal for the industry, for sure. Forget about California and Florida. Normal operations in the Gulf will be overregulated like the N. Sea. And so on.

Wow just posted below and submitted, only to see your post above upon refresh.

Sounds about right, btw free atmospheric hydrocarbons are the Reaper, refinery blow up a bit back with people in unsafely located break shack sound familiar?

Skippy…thanks for your post.

One thing that amazes me is that they started back to work so soon after the cement job.

After bumping the plug on a cement job, I always required the crew to wait a minimum of 24 hours before they touched anything. Everything was completely still. This allows time for the cement to set up, as green cement isn’t that strong. But according to a report I remember reading somewhere, it was only 20 hours from the time they bumped the cement plug until the well blew out.

Whichever of the many reports one reads, they all seem to indicate that within 20 hours of bumping the cement plug the crew had already done a tremendous amount of work. How long did they spend WOC (waiting on cement)? It sounds like not more than a couple of hours.

Cooter,

I found this part of your COMM 2 to be sycophantic in regards to BP’s well management:

“They cemented this casing with lightweight cement containing nitrogen because they were having lost circulation in between the well kicking all the way down.

The calculations and the execution of this kind of a cement job are complex, in order that you neither let the well flow from too little hydrostatic pressure nor break it down and lose the fluid and cement from too much hydrostatic. But you gotta believe BP had 8 or 10 of their best double and triple checking everything.”

Instead of walking this incredibly thin tight rope between blowout and losing circulation, the appropriate thing to have done would be to run an intermediate casing string to seal off the loss circulation zones. That would have eliminated the loss circulation problems so that they could increase the mud weight to whatever level was necessary to control the well without playing this high-risk game.

The fact that this was an exploratory well (wildcat) and they had absolutely no knowledge what they might encounter as they drilled deeper makes this lack of judgment even more egregious.

So Glenn and Cooter, thanks for your added content and discussion here. I now have a far clearer picture of the process prior to the blowout.

Hell, its hard enough to test concrete floor slabs IE: three test points in a SQ meter x distance apart w/relocation after failure to a new test spot less than x from the prior w/three successive fails required to call it a defect, then patch or remove total effected area and re set. Then you have longitudinal tests, compression tests, moisture tests.

Lets tell the little people how much area out of the total is required for certification, not much as it impedes production.

How do you get testing done at 5,000ft, surface samples taken prior to pour?

Concrete at 5,000ft, you have to employ magic to get it right more than not. BTW whats the build warranty on all this stuff down at the bottom of the ocean aka the start of the worlds food chain, all across the world…eh…BP helloooo???

Methane bubbles/gasses unobservable/untestable over how much hydrostatic pressure=(nothing man made can stop it)of raw black death. Heck sounds like they use MDF in a wet area lol.

Isn’t salt water cure a catalyst (fast cure), what are the additives used in this mix? How many pores/sets have been done at this depth or under such pressures, what is the ITP criteria, has all the testing gear been calibrated/zeroed and verified by independent parties.

Skippy…one sure fire way to make a concreter frown…take the cream off the top of his shiny slab after they pour curing agent and send the whirlybirds over it, showing all the spider webs, alligatoring, poorly distributed aggregate, FOD near structural anchoring points, hope your house (anyone) isn’t on one of those floating slabs with styrene fill (Ive seen styrene 3mm under the cream, roach motels).

PS. did they ever resolve and fix that runway at DIA, that place was a mess but, guess who failed upward as ex governor of Colorado, ethnic opportunity contracting my ass, all big boy backed with out of state subbies with tans man…Swedish subbies in the gulf…yawn.

Let’s hope that the oil company executives got paid out with sufficiently large bonuses, earned by cutting corners, so as not to be unduly inconvenienced for this science fiction scale catastrophe. Perhaps this will get rid of those pesky fisherman, nature lovers, and tourists, who just get in the way. Seriously, if they did care about anyone else they would have had a plan in place. The fact is, executives are already paid out, and have no stake in what happens next to their large corporations or banks. An act of unspeakable violence has been done. What we really need to pray for is PEACEFUL change, because any non peaceful change will sow the seeds of its own illegitimacy, and only replace one problem with another .

Reading in The Driller’s Club forum, there’s reference to comment from a lawyer (Becnel) that the plan was to drill down to 18,000 feet, but that they might have actually drilled deeper. Here’s the quote:

“This just in: Becnel tells me that one of the platform workers has informed him that the BP well was apparently deeper than the 18,000 feet depth reported. BP failed to communicate that additional depth to Halliburton crews, who, therefore, poured in too small a cement cap for the additional pressure caused by the extra depth. So, it blew.”

Original source: http://www.truthout.org/slick-operator-the-bp-ive-known-too-well59178

Anybody hear mention of this elsewhere?

Not to mention that Transocean looks like they are raking in a $270m profit from deadly spill

This story is frightening, if the well pressure is 135,000 psi, and eroding the pipe… Houston, we have a disaster… worse than reported.

http://www.opednews.com/articles/BP-Insider-Massive-Dead-Z-by-Rob-Kall-100508-893.html

I’ve read BP said they offloaded the 770,000 gallons of diesel on the rig before it went down?

I am no expert, but 135k PSI is way off the charts. This is like someone talking about their car going 1000 MPH. Off the charts.

The spill, in its current form is closest to the Ixtoc I oil well from 79/80 (http://en.wikipedia.org/wiki/Oil_spill). A disaster for sure, but not the end of the world. This is assuming the well head holds up, its probably going to be similar volume plus or minus a bit.

However, if the wellhead fails this is biblical in scale. And erosion is the way it will happen. Fluid jets are one of the most efficient ways to cut extremely strong materials like steel. If there is enough fluid passing through the well head that fluid will contain small particles of dirt/rock/sediment from the well and it will sand it open from the inside out.

If there are some petro engies floating about, I would be curious how a well is capped when that well is flowing at a high rate (e.g. total well head failure). I am assuming it cant. If the well was just leaking, the main well could be loaded up with heavy mud to build enough pressure to stop the flow. But if the well is flushing mud as fast as it can be pumped it we are seriously screwed.

Along these lines, http://www.OilPrice.com ran an article the other day (http://oilprice.com/Environment/Oil-Spills/The-Cover-up-BP-s-Crude-Politics-and-the-Looming-Environmental-Mega-Disaster.html) which describes what could be a well head failure.

All we can do is hope for the best. I wish we could make better management decisions as a nation.

For the record I am not a petro engy nor do I work in the oil/gas field, so take me with a grain of salt. I have just been reading and trying to learn.

Cooter

There is quite a discussion on this site too that decribes how understated BP is in describing extent of this disaster….could wreck the oceans…will require a explosion to quell this and that MAY seal off this but is this what BP wants or just containment that is not possible…

pesn.com/…/9501643_Mother_of_all_gushers_could_kill_Earths_oceans/

As I understand the situation, Transocean and Halliburton were contractors for BP, responsible for drilling, cementing, etc. this exploratory well. From the post I can see human error is a likely cause for the resulting explosion and deaths, error made by Transocean and/or Halliburton employees. I didn’t pick up anything in the post that supports the post’s title that BP cut corners on safety. What did I miss?

No, Transocean owned the rig, BP leased it, it was BP employees on the Deepwater Horizon. So the “drilling unbalanced” was BP’s doing, as well as this:

As a gas bubble nears the surface, it starts expanding as the hydrostatic column holding it down diminishes. So the return circulation grows stronger and stronger, but not “suddenly,” and not with “explosive fury.” There are warning signs before all hell breaks loose. So somebody was clearly asleep at the wheel. Perhaps this is where another bit of information provided by the NY Times story is important. The NY Times article indicates that there was a big party underway, with four BP executives in attendance. Perhaps nobody was minding the shop.

Halliburton handled the cement job, that was another potential source of failure. Some sources have suggested that the site where the cement seal was installed was deeper than Halliburton was told it was. Glenn also indicates the seal does not appear to have been allowed to set the normal amount of time. Not clear whether that was Halliburton or BP’s call.

What you missed is the fact BP (the operator) designed the well, gave all the orders, had to sign off on each and every step completed by “contractors.” No BOP failure. No human error. BP rushed the work, skipped pressure tests because they wanted to move the rig, and didn’t bother to supervise mud returns.

An Open Letter to Congress http://seekingalpha.com/p/1g3b

Thanks to Glenn Stehle, Cooter, commenters for an informative and on-point thread/discussion. Very informative, I appreciate it. Thanks again.

Hey Yves, I have a nerdy observation. When I watch my episodes of Star Trek TNG, Mr. La Fourge, Chief Engineer, will mention that a certain system, say the transporters, have 7 backup redundant safety systems. Now, being that it is fantasy, I still wonder ‘what would someone today say if we passed regulations on our transporters saying they need 7 backup systems?’. If you watch Star Trek, how often do they have a transporter accident? They often say it’s the safest way to travel. So, it leads me to think that, in our non-regulated society, we would have some transporter benefactor say we don’t need 7 backups, 1 is good enuf. So we cut back to save money and whatever. Until that one transporter accident. Then we say ‘well if we had 7 backups that would never have happened’.

I guess my point is we as a society don’t care about preventing accidents until they happen, especially affecting us personally, then we magically see the light and want to prevent every accident possible.

It is clear from testimony of eyewitnesses that BP’s orders to shortcut safety procedures and the failure to address mechanical failures at the wellhead over a period of many days, plus the loss of drilling mud thanks to too-rapid drilling and consequent subsurface fracturing led to this blowout. It was almost eminently predictable.

BP and its executives who made these decisions should be indicted and prosecuted for negligent homicide in the deaths of the 11 rig workers.

I Thank All Of You For Being On Top Of This & Giving Me THE OPPORTUNITY TO HELP WITH MY IDEA TO CONTAIN THIS LEAK WHICH I FEEL 100% CONFIDENT THAT I CAN DO IF BP; JUST DOES A FEW MODIFICATIONS TO THEIR LARGE 100 TON CONTAINMENT BOX As Described below; (and if nobody tests or tries to put my idea into action and when the top hat fails to work and I will explain why I feel that it may fail, they may be desperate enough after this to try my idea and they probably will still be able to use my idea if top hat fails, but look at how much oil that will be flowing into our oceans if the top hat fails. So it makes more sense to me for them to try my idea first then if it doesn’t work NO MORE DAMAGE would be done. My Idea is completely reversible and my idea can be tried without cutting the head off and contaminating the ocean further, not only that but if they had my modified 100 ton containment box modified and ready to use, which they would have if they would have tested my idea weeks ago then all they would have to do is lower to the ocean floor and place it over the broken unit now, thus minimizing any more oil leaks.

My Concerns on the top hat not working are as follows;

I feel that there are too many unknowns and the biggest unknown is the amount of oil pressure that will be coming out of the pipe after they cut the head off.

1. I feel that being that the top hat only weighs 2 tons that the amount of pressure may be too great to install the top hat.

2. I feel that injecting hot water into the unit may not work to stop the icing problem.

3. I also have a concern of what will be gushing out of the unit after they cut the head off, metal parts, debri etc. which if it shoots up and then lands around the base of the ocean floor will make my idea of trying the larger containment box again impossible or more time consuming to do. I am just using common sense on this stuff nothing more.

So common sense tells me why not try to modify the 100 ton containment box that we know is heavy enough to handle the current amount of oil pressure that is coming out of the well modify it, using my idea to de-ice (if BP or someone else has a better plan use theirs to de-ice, the unit..this isn’t a popularity contest I don’t care who has a better idea) then try this first and if it doesn’t work then try the top hat or something else but give this a shot now: Again I ask what do you have to loose and what do you have to gain by trying my idea ?? Answer; An opportunity to control and stop the oil flow that WILL be missed if you don’t try it now ! ! BP can keep pumping dirt inside the pipe in the mean time while they are modifying the LARGE UNIT minimizing the amount of oil spill until unit is ready to try. Here is my idea again below and I have more to add to it that I just thought of this morning.

I am still trying to help if BP has to go back to A Containment Box Plan or another Plan that needs a de-icing solution, and their Hot Water Injection Doesn’t work here is an Idea that I AM 100% SURE WILL WORK TO DE-ICE and a few other Ideas..

PLEASE PASS THESE IDEAS ON TO BP OR OUR TEAM ! ! ! ” FIX FOR ANY CAP ICING PROBLEM”

Here are a few ideas that I strongly suggest that BP tries in their lab the first one is a contingency plan if pumped in hot water does not work for their Containment Box Plan to stop their icing issue.

CONTAINMENT BOX IS THE ONLY ANSWER TO CAPTURE OIL, ICING PROBLEM ! ! !

HEAT RISES AND WILL RISE ALL THE WAY TO THE SURFACE INSIDE THE DOME OF THIS UNIT AND INSIDE THE HOSE CONNECTED TO THE SHIP, KEEPING OIL HEATED AND THINNED ! !

COAT ENTIRE UNIT WITH RUBBER, ESPECIALLY ON THE TOP INSIDE OF DOME, WRAP HEATING COIL WIRE AROUND AND INSIDE OF UNIT,COAT WITH RUBBER.

BINGO YOU HAVE A RUBBER INSULATED ELECTRIC BLANKET WHERE THE HEAT CAN BE CONTROLLED FROM THE SHIP ABOVE THAT IS SUPPLYING POWER TO THE ELECTRIC BLANKET, NO ICING, THINNER OIL TO DEAL WITH ! ! Just turn up the heat as needed.

THE RUBBER ALONE WILL HELP, LOOK AT A SKIN DIVER SUITE.

THIS SAME METHOD SHOULD BE DONE TO ANY HOSE OR PIPE RUNNING UP TO THE SHIP..HEAT RISES ALL THE WAY TO THE TOP ! !

A FACT, If you don’t believe this statement ask our LEADERS (JOKE)

This Idea is similar to an electric blanket only, (this electric blanket will be made out of rubber), I recommend sandwiching the heating elements between the rubber insulating the unit like an electric blanket inside and out. HEAT RISES and if the hoses/lines that run down are also coated and heated this will help as well.

I recommend installing a very flexible rubber skirting at the bottom of the containment box that will flex around any debri, rocks pipes and create a seal that will keep oil from seeping at the bottom of the containment box. (NEW 5/30/2010, also At the base of this flexible rubber skirting attach water resistant sand bag tubing units that will wrap around the entire base of the skirting to weight the skirting down and help seal off any oil that will try and seep out from the bottom of the skirting. I feel that we can seal off just about ALL OF THE OIL that is POURING into our oceans by incorporating my idea into the LARGE CONTAINMENT BOX NOW. Also as for the power running to the electric heating elements, we can either run external water proof cables of incorporate a internal electric connector that can be installed at the base of the large containment box, that can be plugged into and this would power the internal heating coils inside the containment box. (just run electric cable to the Unit then plug it in, wrap rubber electric blanket on the outside of the pipes to heat those as well, CRANK UP THE HEAT AND WE ARE READY TO CAPTURE OIL, seems like BP would jump on this one just, they could recover some of the oil and it would be thinner, easier to deal with after heated up and capture the largest amount NOW not later..

We Have NOTHING TO LOOSE BY TRYING MY IDEAS AND A LOT TO GAIN ! ! !

I have worked with different types of liquid rubber and some bond very well to steel and brick and is very durable and are OIL RESISTANT and non Polluting..

(Always Striving To Be Part Of The Solution)

Respectfully, Michael V Caldwell “UNITED WE STAND & UNITED WE SOLVE PROBLEMS IN OUR WORLD”