By Jack Lifton, a consultant, author, and lecturer on the market fundamentals of the technology metals

Capitalism with Chinese Characteristics, (CWCC) as the Chinese press officially refers to the use of capitalism by the Chinese Communist Party (CCP) to advance socialism in China, is winning the battle with the neoliberal, “free and efficient,” market that supposedly has led the USA, first and foremost, to “the end of history.” CWCC has transferred enough wealth from the west to the east to ignite self-sustaining growth in China’s GDP.

Our world dominated by two capitalisms; the “free market” variety practiced in one form or another by almost all of the industrialized countries except Russia and a few others with a strong authoritarian bent; and “Capitalism with Chinese Characteristics (their official description) practiced of course by the Peoples’ Republic of China.

Let’s look at how the two capitalisms have fared in creating a secure supply of the raw materials for manufacturing energy storage and production devices for the storage of and production of alternate (to fossil fuel produced) energy. Access to supplies is critical to prevent shortages and to help assure market position.

Notwithstanding the illogical blather about globalization, its purpose outside of China in the last generation has been to enrich a small segment of western society without regard to the welfare of the general populations in those countries. Natural resource imperialism has been the driver of globalization for centuries. But the countries that were once victims of resource imperialism are in the process of turning the tables via total vertical integration of the production, use, and marketing of consumer goods critically enabled by those natural resources.

Specifically, the overarching purpose of Chinese business is to achieve Chinese independence of global markets for the basic needs of a widespread technological society second to none.

The Chinese focused first on the security of a growing Chinese INDUSTRIAL economy by seeking to attain natural resource total supply chain self-sufficiency. The country is now addressing health and safety.

Chinese politicians pursue national objectives through a reestablished mandarinate, a reproduction in part of their own ancient approach to large scale governance by a meritocratically selected and educated elite. They have dded to that a bit of the ancient Roman cursus honorum, the path that a member of the ruling class must take in order to advance to senior roles in their one party government. No Justin Trudeau’s; Eduard Macron’ or even Donald Trump can take power in their system. It does help to be directly descended from a founder of the Chinese Communist Party or its hierarchy but experience in government, and a specialized education, is an absolute requirement for the top job(s) in today’s China.

By contrast, American politicians; public intellectuals; and opinion makers are committed to magical thinking; they hold that beliefs are more important than mere facts. When they recognize a “crisis,” which they define as “when things aren’t going the way they are supposed to go to keep us personally wealthy and powerful indefinitely” their response is to first “study” the problem (to get it out of the public eye) and then after consultation with each other throw money at “solutions” that have been proposed by properly credentialed “experts’ and others who are the “right sort (their class) of people.” Thus we get neoliberal economics with its conceit that a “free” market will always be both efficient and “ultimately” keep supply and demand in balance through directing capital to where it is needed to do so.

The FACT; it is not a belief or conjecture; but an obvious fact that a consumer society built upon technology is completely dependent upon the production of just a few key materials derived from natural resources. This is well understood by the Chinese mandarinate, and since the goal of the CCP is to build such a society, it has resulted in a national mandate for China to become self-sufficient in these key materials for technology as soon as possible. The Chinese are not natural resource globalists; in fact they are natural resource imperialists for want of a better term.

As Mao Zedong said when the Chinese communist takeover was floundering economically, “Let a thousand flowers bloom,” i.e. try everything

His brilliant successor, Deng Xiaoping, decreed that China must quietly become wealthy and powerful, and for this he allowed the first use of capitalism to advance those goals through selecting the best results of letting a thousand flowers bloom.

Today’s Chinese leaders, less charismatic but dedicated to the same goals, have promulgated a modified capitalism (with Chinese characteristics) to achieve self-sufficiency in production and then supply of goods determined to be critical to the future of Chinese society.

And now they are sorting out the various approached to capitalism and the selected target resources to make CWCC as efficient as possible to achieve the goals that have been so identified.

The mandarins convinced Deng that China’s abundance of rare earths was important, because they foresaw that the miniaturization of electronic and electrical devices, the main use of rare earths properties, conserved and extended commodity natural resources such as iron, steel, aluminum, copper, and fossil fuels, thus advancing China’s goal of self-sufficiency. Within one generation the Chinese rare earth supply chain had become vertically integrated and was a global monopoly; this was mostly achieved because China’s construction of a total downstream (from mining and refining) supply chain allowed it also to become a monopsony in the final assembly of goods dependent for their operations upon the electronic properties of the rare earths. This monopoly/monopsony was the intended goal!

Of particular interest today is that China’s rulers have now determined that they must electrify personal as well as mass transportation on the ground in order to eliminate an unforeseen (by them) problem: massive air pollution in their mega cities caused by the concentrations there of fossil-fueled vehicles (which in the general scheme of things globally produce only two percent of “pollution,” but their concentrations in cities are principal contributors to it in those locales).

China’s “President” mandated first that China’s 90 motor vehicle assemblers and 40 lithium ion battery manufacturers produce 5,000,00 electrified (mainly battery powered) motor vehicles by 2020. Then they extended the “mandate” to foreign automakers manufacturing or selling cars in China, and furthermore, required that only Chinese manufactured batteries may be used in motor vehicles made or sold in China!!

The Chinese domestic battery maker’s very first response was that they did not have the manufacturing capacity nor access to the raw materials necessary. The response of the long term goal directed CCC was to use CWCC to “encourage” Chinese mining, refining, and fabricating industries (dominated by SOES) to develop or purchase the critical natural resources and to expand their capacities to meet the needs of the mandate. The Bank of China was ordered to “facilitate” such investments GLOBALLY-but and this cannot be overemphasized-globalization of sourcing for the PROC means the acquisition globally for use IN CHINA of natural resources! It does not mean acquiring foreign sources of natural resources to produce them as raw materials for global markets, NOT AT ALL!

By contrast, free market capitalism has today been almost totally financialized. Its purpose has become the transfer of money to a few, not the creation of new wealth in the financier’s home country through building factories and creating jobs. In fact, the moneyed elites have become what the Soviets used to call “cosmopolitans,” which were the criminals who put self before cause or country. Although it is easier for a Chinese national to “escape’ than it ever was for a Soviet citizen, it is still a crime in China to make or sequester money that is not for the purpose of advancing China’s path to socialism. Expatriates are shunned if they try to return and the amount of capital that can be exported from China for personal use is strictly limited.

With that introduction, let me now look at the influence on world commodity markets of the Chinese goal of the electrification of motor vehicles for personal use. The issues in the west have been driving range and the selling price of the vehicles.

The nebulous goal in the USA is allegedly to save the planet. In China, it is to immediately reduce pollution in the cities. American free market capitalism wants a relatively short term return on capital. CWCCs wants a self sufficient Chinese economy with return on capital to be measured by including the success of the Chinese standard of living and quality of life.

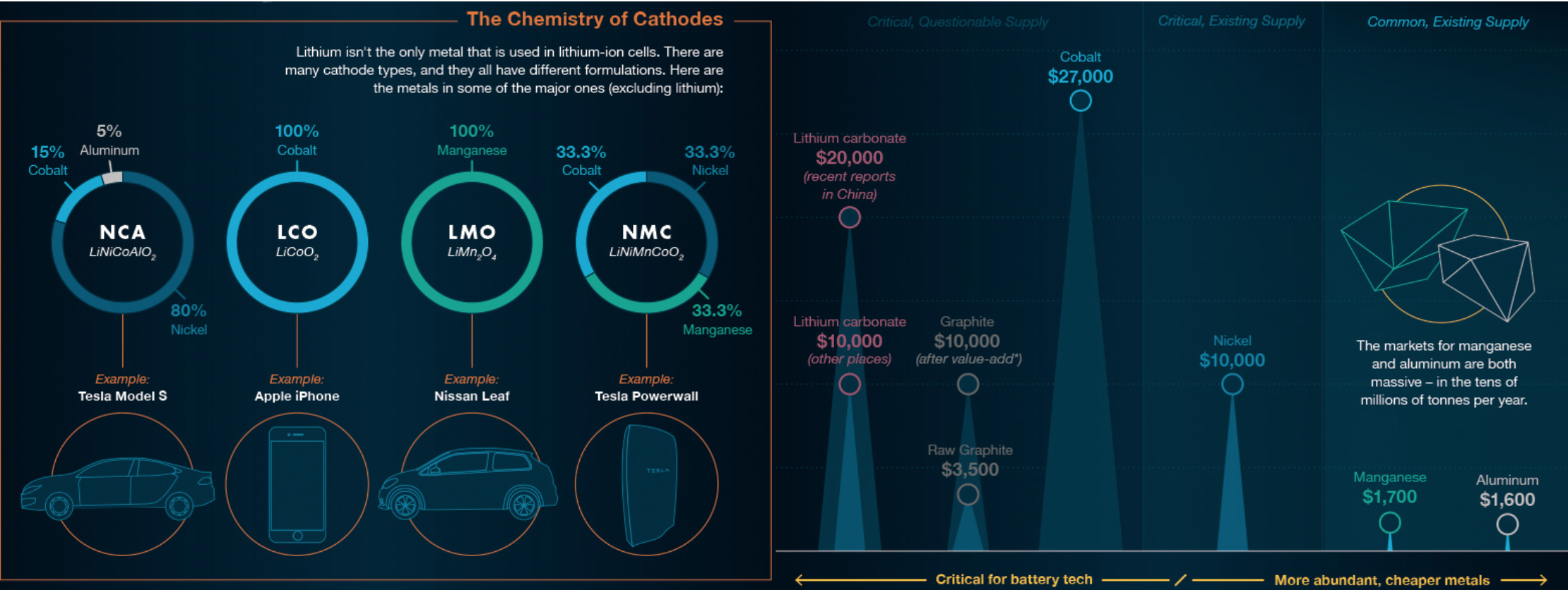

Let’s look at the critical natural resources necessary for producing lithium ion batteries that can give a one to two ton motor vehicle a range of 300 km or more; these would be of the of the NCA, nickel-cobalt-aluminum cathode type such as is used by the Tesla corporation.

Note that the above comparative chart shows that the Tesla Model 3 battery contains only half as much cobalt as the Tesla Powerwall home power battery, for which the Tesla organization projects an even larger market than that for motor vehicles.

Note also that the chart does not state how much lithium would be used in these batteries. For the Model 3 unit that number would be 10 kg, calculated as lithium metal, or 60 kg calculated as the more common commodity unit for lithium, which is lithium carbonate. Neither copper (more than 75 kg), which is not even mentioned, nor aluminum (6 kg) are listed as “critical.” I think that this is because the chart’s author knows that both metals are produced annually in the 10s of millions of tons; 25 in the case of copper, and 50 in the case of aluminum (Note at this point and keep it in mind that China uses and refines from ore concentrates, intermediate forms; and scrap ONE-HALF of all of both the aluminum and the copper used on this planet annually!

As the chart shows there would be 19 kg of cobalt (measured as metal) and 100 kg of nickel, measured as metal in a Model S battery, which weighs around 500 kg in total when assembled.

Let’s see how much of each metal would be used to manufacture batteries for 500,000 2018 Tesla Model 3s.

Cobalt: 19 kg/battery x 500,000 batteries = 9,500 metric tons of cobalt

Lithium: 10 kg/battery x 500,000 batteries = 5,000 metric tons of lithium

Nickel: 100 kg/battery x 500,000 batteries = 50,000 metric tons of nickel

Copper: 75 kg/battery x 500,000 batteries = 37,500 metric tons of copper

Now let’s look at the USGS estimate for the total production of each of the above metals in 2016

Cobalt = 123,000 metric tons

Lithium = 35,000 metric tons

Nickel = 2,250,000 metric tons

Copper = 19,400,000 metric tons

Therefore the 2018 production run of the Tesla Model 3 will require:

13% of the world’s new production of COBALT

14% of the world’s new production of LITHIUM

2.3% of the world’s new production of NICKEL

2% of the world’s new production of COPPER

Now let’s look at where the above metals are refined into ready for use lithium ion battery grade forms. Actually let’s just look at what percentage of all of the above metals are so refined in the PRC:

Cobalt = 60%

Lithium = 50+%

Nickel = 52%

Copper = 40%

But there’s a problem. As I have stated the Chinese do not like to export raw materials; they prefer finished goods containing those raw materials, so that when they do export finished goods (in excess of their domestic needs) they capture all of the value added prior to direct marketing. The overwhelming proportion of lithium ion battery makers are domestic Chinese firms or Chinese dominated ventures with Japanese or Korean firms. Therefore the Chinese market has a monopsony on lithium ion batteries for use in ground transportation.

As an aside at this point I note that according to the USGS the United States imported 11,000 tons of cobalt in 2016. This means that Tesla’s needs alone would essentially double the amount of cobalt imported into the USA by the end of 2018. This would have to be battery grade cobalt produced outside of China, and since the amount of new cobalt produced annually in the US is negligible and China refines 60% of the world’s cobalt, it would mean that the US would require nearly half of the new cobalt produced and refined outside of China in 2018 unless Chinese made batteries are counted as cobalt imports.

Is it possible that Tesla alone could use as much cobalt as the rest of the United States industry altogether? Yes, it is. But is it likely? No, it isn’t. Remember that these demand figures do not take into account any Powerwall Battery production, or the substantial contract Tesla announced in Australia to install a huge Powerwall facility there.

I also note in passing that the USA does not have sufficient domestic lithium refining capacity, not to mention mining capacity to deliver to Tesla 14% of next year’s total global lithium production. And China is well on the way to monopsonizing global lithium use for electrified motor vehicles’ batteries.

At this point, we need to revisit China’s mandate to produce domestically 5,000,000 electrified motor vehicles by the end of 2020. If these vehicles used the same type of battery as Tesla’s Model 3 to achieve a range on a charge equal to that of a medium size fossil fueled vehicle,1 then the Chinese OEM electrified vehicle industry would require essentially all of the 2020 new production of cobalt and lithium under any possible scenario of increases in the new production of either metal. It would also require a substantial increase in Chinese refining and fabrication capacity for battery grades and forms of the two metals. Is that possible? Yes. Is it likely? No, because it would completely disrupt the world’s supply and value chains for cobalt and lithium.

Of course China could opt for a majority of the mandated production to be of shorter range EVs for city driving. I think this is in fact likely.

But China has mandated that by 2030 30% of all cars manufactured in China must be EVs. Based on today’s 25 million units per year (the world’s largest production in one nation) this would be 7.5 million EVs per year, a figure which would have been reached by building on 2020’s 5 million units! This would mean an average production of 6 million units per year, so that by 2030 China would have manufactured 60 million EVs!! The modern lithium ion batteries for long range use are intended to last up to 10 years, so that the Chinese production alone would tie up (immobilize and therefore be unavailable for recycling) several years of global new production of cobalt and lithium and impact even the global supply of nickel and copper.

In the USA and Europe range is more important than in China, so the projections of increased penetration of those markets by long range EVs, such as the Tesla, should add just as much demand in those two markets combined as in China.

Short sighted speculators will try and corner the cobalt and lithium markets surely. Realizing this is one reason that Chinese companies are acquiring cobalt, nickel, and copper properties and mines aggressively right now. The Chinese government is very much encouraging this.

I suspect that long range EVs using cobalt based cathode technogies will ultimately be the status symbols of the wealthy, and that the world’s EV fleet will be powered by shorter range power trains using more available cathode materials.

This scenario will allow cobalt prices to increase to where they would have to be for free market capitalism to “invest.’ In the meantime capitalism with Chinese characteristics has basically won the race to be the first to mass produce a mix of city and country (longer range) EV’s that are affordable in their markets. I suspect that Chinese car and battery makers are already planning sufficient production so as to be able to export “surplus’ EVs of both types to the US, European, Asian, and African markets by 2020.

The best way to invest in the projected EV market boom is to invest in producers, refiners, fabricators and recyclers of the cathode materials for lithium ion batteries for motor vehicle and stationary power use. Stay away from the non-Asian car makers; they have not understood critical raw material constraints and that misunderstanding is about to bite them in the tailpipe.

Norway, the UK, and Germany can ban fossil fueled cars by 2040, but by the numbers it will be the Chinese car industry that benefits most from this move.

Don’t say I didn’t tell you so.

____

1 In an earlier post on the importance of cobalt to the production of electric vehicle batteries, some readers objected by saying that other battery technologies that did not use cobalt were close enough to be commercialized so as to make this concern moot in a few years.

The problem with this reasoning is that the automotive industry has long production lead times. And at least as important, the OEM automotive industry investment in innovation is subject to the herd mentality. No where is this more true than in “advanced” anything (here read “battery”) technology.”

The global OEM automotive industry was very little investment (or interest) in proulsion battery research prior to the 21st century. EVs like flying cars, were viewed as marginal and niche markets at best. Then, as always, a “major” stepped into the water about 25 years ago. Toyota took an idea pioneered by (the soon then to be defunct) International Harvester personal vehicle manufacturing division (anyone remember the Harvester “Scout?”) called the “hybrid” power train and created the Toyota Prius NOT TO MAKE THE WORLD GREENER OR TO REDUCE THE IMPACT OF (THEN CONSIDERED HARMLESS) MAN MADE CARBON DIOXIDE, but to meet California’s then requirement of 2% zero TOXIC emission vehicles in a company’s product line.

Noting that GM’s EV1 was going to be (and was) an economic flop, and considering that failure to be due in part to the weight, maintenance required, hazard of fire(!), short cycle life, and power disadvantages of lead acid batteries, adopted a then “new” technology known as the nickel metal (rare earths) hydride battery, which ameliorated the dangers of lead-acid and even though it cost more to build, it added 50% to the RANGE!

Fickle, perhaps bribed, California politicians rescinded the zero emissions mandate at the last minute and GM scrapped the EV1 program as fast as it could.

But Toyota felt that its approach has created a “new” product, so it introduced the Prius into the Japanese market in 1997, where it became a success and is still in the product line today, 20 years later.

Fifteen years after introducing the Prius, Toyota began selling a plug-in version using a lithium ion battery. The company today still offers the nickel metal hydride version of the Prius, but has announced phasing it out in favor of the lithium ion battery. Total product cycle time expended since the Prius was first engineered has been TWENTY FIVE YEARS. Note that only Toyota has had this profitable result with nickel metal hydride batteries. GM introduced a hybrid Buick in 2008 using nickel metal hydride technology, and all 8,000 units had mechanical battery failures! Ford waited longer and went immediately (after 3 years of production part approval process, PPAP) to a lithium ion battery.

Disruptive some technologies may be, but their adoption by manufacturers of civilian goods is at the margins, and profitability and product differentiation are the drivers NOT JUST INNOVATION.

Globally, after ONLY 10 years of study, OEM car makers have chosen cobalt using cathode chemistries requiring liquid electrolytes and graphite anodes for long range electric power trains. Toyota is once again an outlier looking at solid state electrolyte lithium ion batteries. In 25 years or so this technology, or that of fuel cells (solid state but not using platinum group metals or scandium, neither of which are abundant enough) may displace liquid electrolyte cells. But then again they may not, even if they work and work well scale up may not be possible due to critical material constraints or mechanical or electronic issues. It’s a crap shoot and magical thinking about moving innovation from the bench top to the showroom disruptively and immediately won’t help.

The argument “it was so, hence it will be so” at the end is somehting I don’t really buy. Yes,lead-time in car making is long.

But I don’t see (of course, I’m no expert, so could be miles wrong) a reason why if someone was able to produce the same physical form batteries as they are used in cars at the moment but had much better characteristics (and, crucially, be safe), the carmakers wouldn’t use them in single years, not decades.

The lead time problem here would be production of the batteries, not car production. The AA batteries I put into my 20 year old alarm clock are much different from the ones I put there 20 years ago, yet the clock doesn’t care. I understand this simile may be way wrong, but I’d like to know exactly why.

Of course, relying that a better way/batter will be found is foolish. But discounting it pretty much entirely is not smart either IMO.

Different batteries have different form factors, for starters. Cars have “platforms” and the trick for maximizing the profitability of cars is to use the same “platform” as long as possible. Introducing a new battery means abandoning a platform early and incurring tons of design and retooling costs.

I worked on an advanced battery study for cars in the early 1990s. The underlying economics of auto manufacture haven’t changed. The lead times are very long and the economics of manufacturing are the reason.

This has changed, in two ways, as per below, all made possible because while specific energy is still not very good – gasoline has great energy density, 75lbs will take you further than 1000lbs of battery packs – it’s sufficiently better to make nice electric cars possible (though not necessarily affordable).

1. Today a battery pack can be modified into irregular shapes hence fit into an existing platform. Lots of tradeoffs, but that’s engineering as an art. The Renault Clio and ZOE are the same platform, made on the same assembly line.

2. The next generation of platforms, as the various OEMs roll them out (and they’re now moving towards sets of front-end modules etc so “platform” is no longer fully accurate), anyway, the next generation are being designed to allow “flat” battery packs, which provides better driving performance and better pack architectures. I was through Renault’s “competitive teardown” facility early this summer, that’s one of the things they look for in weld points and suspension placement of new platforms.

The challenge remains batteries, though the power control module is still by itself as costly as an internal combustion engine, and you still need an electric motor and a battery pack. The former two are amenable to standard learning curve cost reduction. In contrast the chemistry is proving very stubborn, and without the chemistry, the normal “learning curve” cost reductions won’t do the trick. Even if one of the “breakthroughs” announced on a near-weekly basis actually pans out, the path from laboratory to test cell, test cell to vehicle testing to initial low-volume production and then the ramping up of production for an initial vehicle will take at least 10 and more likely 15 years. Only as volumes increase can realized costs actually fall – the first vehicle in which a new battery is “launched” won’t be a high-volume product, that’s the only way to cover the combination of initially high costs and initially low production capacity. [However, such new batteries [which make sense only if they have better performance are smaller] can be incorporated in existing electric vehicles quickly, so I can tell an optimistic scenario where we see more electric vehicle volume after 2025. But not before then, and the normal logistics “S-curve” rollout of new technologies will still apply.]

… I’ve already gone on too long, but your fundamental point remains: the auto development cycle is many years long, and no OEM, not even VW, has the engineering resources to work on more than a couple vehicles at the same time.

PS: automotive trivia: there’s one GM EV1 left in operating condition, in Kokomo IN. I had a chance to ride in it 2 years ago in between presentations by Delphi engineers on EV power control electronics. The only other extant EV1 is in the Smithsonian, drained of fluids for preservation purposes. All the others went to the crusher.

Thanks for updating me on how automakers are designing around what were formerly called “platform” issues, as well as confirmation on the more fundamental issue, the length of time to refine and implement new technologies.

If I understand it right, what you’re saying it is that the major development cost of the electric cars is the battery, and bringing that online is going to take a long time. I agree with that – but that’s a different argument from saying that the cars themselves will have to change when a battery technology changes.

The major difference is that if a stable battery technology that improves the results by tens of % comes, there will be incentive to move quickly, because it makes a lot of difference to the final user – as opposed to squeezing a few percent of what a combustion engine can do. Moreover, the battery technology, unlike petrol engines, is not used only in vehicles, so there’s a a much wider user base, with much wider potential customers (that doesn’t mean there’s no challenge between a battery to power a laptop vs. a vehicle, it is, a large one, but there’s something to build on).

As you say, I can see an optimistic scenario of entirely different, but productionised, battery type by 2025/2030. That’s not say that a pessimistic scenario, of not having anything better in the next 50 years or more is entirely improbable too.

Hi Yves,

Setting aside economics somewhat for a moment, what’s your perception of Tesla’s manufacturing and general product development process? It seems they have come pretty far pretty quickly (8 years from founding to Model S release). It seems they approach car production more from the viewpoint of an electronics manufacturing firm, than from one of a traditional automaker, and they can skip a lot of the drivetrain development, since their systems are much simpler, physically.

AFAIK, there’s no physical reason for batteries to have different form factors, especially for solid-state batteries. Say Li-Io batteries alone have a wide range of form factors, from small pill to large blocks.

I understand the platform bit, but especially because of this, if one assumes that batteries will evolve in the next few years, it would make a lot of sense for the manufactures to build the platform modular in respect to the battery (i.e. treat it as a plug-in).

Additional bit here is that fossil-fuel car industry is fairly stable, with high costs for new entrants. Electric cars, on the other hand, are I believe a different game.

First, while you can re-use some of the existing vehicle design, it’s still a new platform. Which, as you say, is expensive – but I’d argue more so for an existing entrant than a new one (mostly politically). But it also means that if someone produces extremely great battery, but which just physically has to be in a different form factor than the current ones (say it has to be a sphere), a newcomer can corner the market. No-one will buy an electric vehicle that can do 200 mile per charge if they can, for similar price, get one that does 400. You don’t get that sort of differences with petrol engines, they are very mature, and improvement even in 10s of % are pretty much physically impossible now.

Also, electric motors are much more widely used than combustion motors, and fundamentally different. Majority of petrol combustion engine expertise is with the current car manufacturers (diesels is slightly different, although the ship diesels are very different from car diesels). Not so for electric motors – and given the wide use of electric motors, it’s unlikely the expertise will be so concentrated.

Given that some platforms carmakers do are already modular (just look at VW from 2007 onwards – MQB platform has vehicles as different as Golf, Audi A3 or Skoda Kodiaq), allowing for battery modularity should be relatively simple.

” the “free market” variety practiced in one form or another by almost all of the industrialized countries except Russia ”

How is Russia not a free market economy??

Vlade,

The AA batteries you put in your alarm clock are very different from those you bought 20 years ago; they last longer in use, have longer shelf lives, and use much less toxic materials in their construction. This has been achieved by marginal advances in manufacturing technology and in electro-chemical engineering accumulating over the last 20 years NOT by disruptive technology.

The “lead time” for the development of today’s rechargeable lithium ion batteries has been more than 40 years. Panasonic (or Sony) first produced them for the marketplace in 1980 after several years of research.

Instant replacement of mass produced technologies by “better ones’ is magical thinking.

Thanks for the comment

Jack

Cd’s vs records. That was pretty fast.

Smartphones vs former types. That was pretty fast.

PC’s vs mainframes. That was pretty fast.

As I recall, anyway…

Don’t confuse technologies that benefit from miniaturization with those that don’t. We’ve seen continuous (and massive) improvements in computer technology because the technology keeps getting SMALLER.

My first computer features a 5 MHz 16-bit processor with a 20-MB hard drive. My current computer features a 3000 MHz multi-core 64-bit processor with a 2-TB hard drive. It is more powerful and capable by many orders of magnitude, and it was cheaper. But all of this is because of miniaturization. Smaller transistors means more functionality for less cost and space.

The same doesn’t apply elsewhere. My most recent car is only 30% more efficient than the first car I drove. And it wasn’t any cheaper at all. Both cars featured the lead-acid batteries of about the same size. Both had similar sized engines and about the same driving range. Sure, the newer car is cleaner, more reliable, and has a better stereo, but that’s after 30 years of incremental improvements.

And has technology improved the cost-effectiveness and performance of kitchen appliances, houses, and furniture? Maybe in a few corner cases, but in most places, no. There have been no “quantum leaps” in kitchen, house, and furniture technology in 60+ years.

Batteries and solar panels don’t miniaturize. They don’t have climbing clock speeds. If you make a half-size solar panel and a half-size battery, you get half the watts and half the amp-hours. Period. Only after long periods of incremental improvements would I expect any improvement.

Predicting that you’ll see massive improvements in battery technology in short order is naive. Planning your economy around such predictions is flat-out foolish.

I think there has been a big change in clothes washers. Front loading clothes washers are much more efficient than top loading washers. Front loaders are very unstable, as it turns out. If you think about how they rotate against and then with gravity this will be obvious. Top loaders spin with axis parallel to gravity, so they are inherently more stable. But better control devices can turn an unstable system into a stable one. By control devices I mean smallish computational devices attached to the motor speed controls that speed up or slow down the motor in response to instability.

In general, controllers have changed a lot of games in the last 60 years, including things in the home and kitchen. You might not notice them, but they make a lot of things possible. There are a lot of embedded computers in cars, say 20 to 30, to control windows, power mirrors, the engine, the fuel system and cruise control. The first cruise control systems were entirely mechanical, with springs and levers measuring speed and controlling the acceleration. Now it’s all a C program implementing a control model, probably created with Simulink.

The difference is all of those things are inexpensive and won’t kill you on a highway. If a CD player cost $30,000 and could blow up your house if not operated correctly, you would give its purchase much more consideration over your trusty old record player.

Batteries serve to store energy — not to process it (like a motor). A better analogy in the electronic industry is therefore to compare various data storage media.

Since the 1950s, there have been basically four of them:

1) magnetic tapes;

2) magnetic disks (HDD);

3) optical media (CD, DVD, BlueRay);

4) flash memory (SSD).

In 60 years, basically 4 types of storage. In each category, there has been faster evolution — but still: the various CD, DVD, BlueRay, types were developed in the course of 30 years. It is actually quite difficult to have

a) permanent storage that is retained for years or decades;

b) that can store a high density of information reliably;

c) and that can access (write and read) it fast.

Battery technology is in that sense more similar:

a) retaining energy for a long time;

b) with a high density of energy;

c) and that can be charged and released fast.

Similar issues, same slow evolution from one technology class to another, with lots of rapid, small evolutive steps within a class. And with batteries just as with data storage, no new class entirely replaced previous technologies; they continue to exist because they have a role to play in different contexts.

Switching from fossil fuel powered vehicles to EVs is absolutely not the solution to any major problems that we face. A massive reduction in vehicles, regardless of their propulsion source is.

Technofixes are not going to save us from the effects of climate change, social unrest, inequality, etc. The only solution is a massive restructuring of societies, globally. Industry of all kinds must be scaled back dramatically. Infrastructure slimmed down (the feet dragging of the US to repair, replace, upgrade our existing infrastructure can actually be a good thing in this case, leaded kids notwithstanding).

Survival and jobs must be decoupled. A good chunk of individuals should not be doing anything we today would call a job. Massive amounts of already built commercial, industrial structures must be abandoned, demolished, the sites reclaimed.

No new homes larger than 1000 square feet should be permitted.

Such luxuries as travel and certain forms of entertainment must be phased out.

Many will see the above as massive sacrifices. This is only because of the dominant culture which has existed for the entirety of one’s life has repeatedly told them that these are valuable, sought-after goals. The costs of achieving such “valuable” goals is immense, immoral.

We are unlikely to do any of this of course. And we will pay dearly for it, though the costs will fall disproportionately upon those who have contributed and benefited the least from such goals.

Excellent observation. The roadway congestion (number of vehicles on the road) remains no matter the propulsion source. (CO2 may be reduced, but road rage remains.)

Yeah, I was thinking the same thing. It seems that the gist of this article is, we need more efficient state-directed capitalism. I’m not seeing how that will help anything long term. Illusions are maintained, mandatory consumption is ensured. In addition, I have had the gut feeling for a while that the more Neoliberal side of the capitalists in the West, as opposed to the Austrians, et al. have been tip toeing their way to the Chinese model for some time now. I’m all for heterodox approaches but we will never simply buy or produce our way out of our ecological and social problems.

As a brief aside, much of the carbon cost with EVs is buying new. People contribute less carbon buying used vehicles or simply driving the one they got until the wheels come off, but as we all know this curtails consumption which is a non-starter for capitalist economics to function.

” It seems that the gist of this article is, we need more efficient state-directed capitalism. I’m not seeing how that will help anything long term”

Then you might have to read the article again.

It will precisely help in the long term because it focuses on long term objectives rather than short term free market hit-and-run.

It cannot be more obvious. Chinese state capitalism is building a monopoly in the materials which will be the key of future techonolgies while the efficient companies of the free market paradise are too busy buying back their own stocks.

By the way, these very same mercantilistic, state-driven proteccionist politics ensured the hegemony of the industrial european countries (and the us) over the rest of the world. Free markets and free trade are only for losers.

It is no coincidence that the very same regions where free trade and free market was imposed nowadays are known as the third world.

The US was very attentive to the need for the military and private sector to have adequate access to critical materials before the fall of the USSR. You can have the government and think tanks prod industry well short of having “state directed capitalism”. However, those days were also before US public companies became as ludicrously short-termist as they are now.

Yes but both long-term and short-term goals seem to involve infinite exploitation of a finite planet. This future tech they’re locking up the materials for is not something we need, not something that will create more benefits than harm, not something we or the other beings we share the planet with can afford.

State-directed degrowth is what we need. That will involve some of the tactics used by China, but for radically different goals. We can either wind-down our current setup voluntarily, in a controlled fashion, or we will be forced to involuntarily, chaotically.

We’ve been overshooting our limits, both resource and moral, for quite some time. This particular timeline of what we call “progress” is in fact a dead end which ends in massive suffering for many; in fact we’re already seeing such suffering.

Who is going to afford all these new EV’s, the boomers (those most likely to be able to afford them) will largely be gone, car loans are already pushing past a 5% default rate and climbing (this without even a stutter in “growth”), and wages the world over are stagnant or decreasing.

Are they (manufacturers) going to be giving them away, or are they going to extend terms to 30 years? Otherwise about 10% of the population will be in the market. To everyone else they are just going to be another unaffordable luxury.

This all besides the point that one ton of steel and rare earth is an extremely inefficient way to move about, even if it is “green” (which it’s not).

It’s all somewhat entertaining, Auto makers don’t seem to grasp yet that stagnant wages mean consumers reduce costs, and the giant depreciating metal brick on wheels is going to get cut a lot more.

I have more than a few friends who leave the car in the driveway and get around by bike or bus.

Tucson is super bikable no? How are your pedal peeps holding up with the heat this year? North of you it’s been reverse cabin fever after 5:00 AM til the monsoon, thank the butterflies in Tokyo – although we did lose the main library to water :(

Good points. The immediate quadrupling in longevity of an electric drivetrain itself might encourage people to move out to 10, 12 years on an auto loan.

But the thing will still rust* in our Rust Belt areas so not real confident about the sense of that. Well it was a fun 75 years until everybody’s freedom of movement started interfering with everybody else’s.

*Actually I thought they had that pretty much knocked in the 90’s, but now cars seem to be rusting again. And trucks are really bad.

“Stay away from the non-Asian car makers; they have not understood critical raw material constraints and that misunderstanding is about to bite them in the tailpipe.”

Does this mean what I think it means: Tesla is doomed, or is it just hobbled by supply constraints?

I think the way to see Tesla is that it serves a strategic purpose like those provided by Raytheon, Motorola, Texas Instruments, Unitrode and whatnot of the Cold War. The Cold War ended, the military went COTS, and they “ended”.

Tesla similarly gets oodles of “free”-market funding to develop the “next things” in the proper capitalist / competitive way. China does the same, but directly, broader, with little waste in the form of retarded millitary adventures and defense against imaginary threats.

“China First!” is enough political justification for them. Which is refreshing.

If Tesla was a commercial venture, it would move to China. Where the market in “next-things” is.

Which goes a long way towards explaining why these sort of material disadvantages barely register with the American public as a looming problem, yet they go all chicken little over the fraction of US public debt the Chinese own. Magic post-scarcity thinking indeed.

Trading treasury securities for useful scarce resources could have been a very good deal.

I believe the real problem is the shifting of USA manufacturing overseas (and not all was shifted to China) with the resultant loss of expertise in the USA and the resultant training of one’s foreign competition.

Meanwhile, economists emphasize the “consumer quality gain” for the USA television viewer watching their imported, and low cost, big screen high-def.

The USA needs a citizen centered industrial policy, instead it has a “preserve financial industry and MIC at any cost” policy.

But for now, the USA can trade dollars for valued items.

That’s one of the biggest factors preventing moving a lot of manufacturing back to the US from China and elsewhere. It’s not that we can’t train workers to do the mundane tasks, it’s that the manufacturing management who have the years of experience in what makes an electronics factory hum smoothly are all overseas. We’d have to import their industrial engineers.

A related issue is that American universities, like American businesses, are not focused on the advancement of the nation, but on their personal advancement compared with peer institutions. This strategy seems to necessitate filling all science and engineering graduate programs with “international”, mostly Chinese, graduate students. We all get to feel good about our sought after universities but where is the expertise migrating to? Hint, it’s not Peoria or Youngstown.

At a higher level, you could argue that all technical education is devoted to turning resources into convenience and fun, whereas it should now be devoted to how we can survive and avoid annihilating each other in a resource constrained world.

But the US should prevail:

* Because Markets.

* Go die.

Please note that this is sarcasm.

>a range of 300 km or more

A ha! I was whining about the “300mile” range (as well as Ludicrous speed) as being pointless and something the Musks of the world just “have to do” in order to

a) Make people not have to examine their driving habits very closely. We’re Americans, after all, can’t expect facts to get in the way of our self-centered stories

b) Prove they can “replace” a gas powered vehicle with this technology

The sleight-of-hand change to kilometers was something that never occurred to me. Anything north of 150miles, with charge-overnight-in-your-own-garage covers like 98% of us. And like I said, rent a nice minivan for a no-worries vacation.

The 300 mile range can be fixed. Just have a charge station and trade in your nearly empty battery for a fully charged one. Like gas you pay for the charge. Also, helps recycle defective or old batteries as well.

I was thinking with my car, when I fill up (not completely full, just about 75%) the gauge in front says est. range 400KM or 240miles and that lasts me almost a month of normal driving.

300km is 186 miles, not 150. And as I said repeatedly, several things matter in what a buyer wants:

1. Variance, not average. You can have a low average but plenty of people, ESPECIALLY in the West, where distances between cities are large, will drive over 200 miles a day regularly and can still have a low average

2. Cold weather. As Grumpy Engineer and others discussed at length, if you live in colder climates you always set out with a minimum of a half tank of gas because if you get stuck, you burn a lot of fuel just keeping your car warm.

You also forget that the consequences of running out of power are way more difficult to remedy with an EV than a gas powered car. That means drivers need much bigger safety buffers, fuel-wise.

I own a Nissan Leaf, and in the first few months of ownership nearly experienced just about the worst case dead battery scenario. I foolishly tried to drive the car from Denver to Breckenridge, in cold weather. I stopped halfway up the mountain to have dinner and charge, and thought I had plenty of battery to make it the rest of the way.

The remaining distance meter went to -0- in the middle of the Eisenhower tunnel, the longest tunnel and highest point in the US interstate system. With no shoulders, and heavy traffic. Not a good spot for a breakdown, to say the least. Fortunately it kept moving through the tunnel and the long downhill on the other side gave me enough regenerative charge to limp into the Frisco Whole Foods and hook up to their charger.

Range anxiety is real.

I wonder why none of the major car manufacturers include super capacitors / ultra capacitors in the power system? Specifically, the kind of stacked-cell technology developed in Russia during the cold war, and implemented there for over 25 yrs? (Note this is NOT the Maxwell-type wound cell supercapacitor, which is toxic, prone to failure/explosion, and has a narrow operating temperature range.) They us aqueous-type electrolyte, don’t include hazardous materials, and they DRAMATICALLY reduce the battery size required, since the supercap supplies the upfront high-power needs (e.g. starting a diesel train engine even in Siberian temperatures with a fraction of batteries that are old and decrepid; better-quality x-rays using mobile x-ray vans with less patient x-ray exposure; power quality “smoothing” eliminating dips and spikes important for equipment and power networks; great for tramways and other transport applications where one wants to absorb energy e.g. braking as well as supply it for initiating movement; think elevators! cell phone chargers!). The stacked cell supercaps can be easily combined for high-voltage applications.

Most battery applications would be far more efficient (and require less and lower-spec battery) if combined with supercaps.

This technology could be integrated currently. It’s probably not technically “disruptive” (and after all it’s been in use in Russia for decades) but as Jack Lifton accurately describes, the car manufacturing industry is incredibly conservative.

Last I heard a few years ago there were some Asian battery manufacturers who were starting to do something with this technology but I haven’t kept up with it. But you never heard anyone talk about the incredible advantage to power density that comes with stacked-cell supercaps, and without requiring semi-exotic metals like lithium or cobalt.

Capacitors supply energy faster for requirements like starting engines, but do not store much energy, so one must look at energy density, not power (delivery rate) in considering vehicle batteries. Big capacitors are usually chemical storage like batteries only with higher delivery rates. I’m sure that battery designers would use any technology that has the energy density and meets the other requirements.

Supercapacitors are different from regular capacitors. They fill and discharge in a fraction of a second. Their use in a power system is WITH batteries, not as a replacement for batteries. In many (or most) starting applications, a big spike of energy is required at the start of something. (E.g., when you switch on your computer, a machine, a diesel engine.) This high power requirement might last only a fraction of a second up to just a couple seconds. After it’s started, much less energy is required.

When a supercap is included in a power system it supplies the high-power, short-term power. Since the batteries don’t have to supply that function, far fewer batteries are required for the total system.

I know wherof I speak, having served on the management committee of a multi-year european project on this topic, including specialists from Russia, over Europe and beyond. It included successful trials outside of Russia, since most of the prior experience with this technology was within Russia.

Supercaps (STACKED CELL ultracaps) are only one component of an efficient power system. They don’t replace batteries but make the whole system less costly, more effective and better environmentally. More research has been done in the former USSR countries. My guess is that Maxwell and others use WOUND CELL ultracaps and they dominate the US-linked market. They’d have the muscle to keep out competition.

couple of minor points:

1. rare earth minerals are not that rare. Main reason they are sourced in China rather than California is that the Americans recognize at least partially the cost of mining externalities and the Chinese government doesn’t, which is the reason for the high level of pollution in China. Since the cost of externalities is pushed off into the future (maybe), Chinese sourced rare earths have a competitive market advantage.

2. Even though China produces a lot of coal to feed their industry, it’s at a high cost in lives and ground transportation. Australia is able to mine and ship coal and iron ore to the Chinese coast cheaper than it can be produced locally.

Neoconliberals don’t actually believe in markets. It is merely PR to hide their underlying authoritarian motives. They don’t actually trust individuals to make their own decisions. They crave dominion over others.

For fans of the old ‘Star Trek Next Generation’ TV show….

Neoconliberals sound like the Pakleds. “Make it go. Can you make it go? We are strong! “

I always thought they were more like the Ferengi with their Rules of Acquisition.

Yes, that’s a great reference. And I notice the wiki page for them is comfortable with using the word theft to describe some of their actions.

If only our intellectual class today could speak so plainly about contemporary actors.

Keep an eye on the battery charging and protection circuitry in real life usage. Even people I thought would be experts on this, seem to just pick ones that seem to last well (Tesla, Prius), or trust that all batteries will be similar in performance durability and quality (Nissan Leaf original batteries seem less well engineered as far as cooling, monitoring, and perhaps management of charging to enhance life expectancy). My 2001 Prius started with batteries that didn’t last as long as expected, but the modules were replaced with second generation ones that have taken me over 287,800 miles so far. I suspect they are better constructed and have a more conservative range of use (40% charge to 80%) that helps them last far longer (perhaps Nissan will improve theirs similarly, once they get more experience with them).

Being an inquisitive type (with what I consider sufficient electronics safety experience around radars, chemical safety around lead acid, Ni Cad, NiMH batteries,etc), I’ve carefully pulled some battery packs apart, and found pictures (wikipedia, for one) of the internal protective circuitry that senses temperature, converts and regulates voltage, monitors the state of charge, etc, to do things we never could “easily” do before. Charging new aircraft batteries involved expensive chargers and a lot of personal observation of time and temperature, vs charging rate to get the batteries off to a good start. Even the best technicians I knew didn’t always follow the manufacturer’s instructions and cautions on new batteries and ended up blowing them up.

To me the new batteries are modern marvels, but the technology that makes them so simple to operate safely also produces some false confidence that they can be treated as carelessly as old batteries (charged with very inappropriate old equipment). I meet many otherwise very competent people that tell me stories about the lousy new batteries that fail too quickly, but in every case so far, it has been due to using inappropriate equipment, or letting the batteries sit far too long, so the one that self discharge more rapidly are too far below the low charge threshold for most chargers.

I am old enough to recall people who had trouble with new technologies like automatic transmissions, but feel we will get through this, too, and really enjoy the benefits made possible as much or more.

Half a million Telsa 3 car batteries, each at 60 kWh, adds up to a total of 30 GWh of energy storage. This is slightly more than the 22 GWh of energy storage that the pumped storage station in my neck of the woods (Bath County) can hold.

And these numbers are utterly dwarfed by the hundreds of TWh of energy storage capability that the world would require for an electrical grid that runs on 100% renewable power. The exact number varies depending on the assumptions that are made, but the following two studies came up with 420 and 500 TWh respectively:

http://ac.els-cdn.com/S1876610214001702/1-s2.0-S1876610214001702-main.pdf?_tid=5dcc2304-76bd-11e7-b4df-00000aab0f26&acdnat=1501594315_b68a086fd6e35f198a0ad306108424d0

http://euanmearns.com/the-quest-for-100-renewables-can-curtailment-replace-storage/

This is about 15000 times what Tesla plans for the Model 3, and Jack Lifton has pretty firmly established that Telsa is pushing the limits of resource availability with their much more modest effort. I don’t see how we’d ever close a 15000X gap.

Why are you assuming that all stored energy is in the form of Tesla battery packs?

I’m not. But if you read articles about grid energy storage systems, you’ll find that most of them assume batteries using the same lithium-cobalt chemistry that you see in Tesla battery packs. A few assume other battery chemistries, but they’ll have resource constraints as well.

People with more clue argue for pumped storage, given that it can readily scale to GWh sizes, but siting requirements limit the amount we can deploy. You need good places for both upper and lower reservoirs close together, a decent barrier between the two, and a source of make-up water to compensate for evaporation and seepage losses.

If you’re willing to move a LOT of dirt you can do more, but here in the US, we’ve become allergic to such giant earth-moving exercise. I’ve seen people freak out because power companies wanted to cut down a band of trees across a mountain range to make room for a high-voltage power line. Imagine the uproar if they started tearing giant holes into the mountains for pumped storage reservoirs instead.

I don’t think you can correlate a hole in the ground with a 150 mile high voltage transmission line through fire prone terrain and using various bait and switches to sneak it through. The sunrise powerlink, which you may be referring to could easily be viewed as a raw deal by the residents in east san diego county. People aren’t opposed to projects as much as they are opposed to graft, corruption and manipulation for private gain, as is rampant in california…more appropriate comparison: nikes deal in oregon, boeings deal in washington, and sempras deal in so cal etc…

I’m wasn’t referring to the Sunrise Powerlink, but all the arguments sound very similar what I’ve heard about various HV lines running through Appalachia. And I’ve heard such arguments concerning wind turbine farms and pipelines, also. Accusations of corruption and undeserved private gain, combined with apocalyptic predictions of pollution, erosion, fire, and other environmental damage.

And in terms of actual environmental effects, pipelines and wind farms and HV lines are all trivial compared to what you’d see with a pumped storage excavation. For a GWh-class station, several thousand acres of forest would be destroyed. Millions of cubic meters of dirt would be moved, necessitating hundreds of thousands of dump truck runs. Construction would take over a decade. Groundwater tables would be altered for miles. And we’d need multiple new high-voltage lines for interconnects to the grid.

Even worse, much of the property would be seized under eminent domain. And at the end of the process, a private company like Dominion Power would use the station to make money.

Does any of this sound familiar?

As someone who lives in Rockbridge County, it’s all very familiar. Talk to the people in Wintergreen (Nelson County) who are incensed that the view from the deck on their estate might change over time. Now, do I want to buy up the two lots adjacent to me to forestall future development, so that all I continue to see are trees? That will be a true “opportunity cost” measure of how much I do or don’t value aesthetics. Showing up at a meeting is cheap talk. [Sorry, economist’s jargon.]

Oh, I I’m working on a paper on supposed “disruption” in the auto industry, and a book out as of Jan 1 on Amazon on the global auto industry through the lens of technology. But I’ll post replies to 1-2 comments after reading everything. Procrastinating on said disruption paper.

ok that is a really big hole. I imagined something much smaller, thanks

Yes. The reservoirs found on large pumped storage stations are HUGE. Man-made lakes essentially. And we’d need THOUSANDS of them to support a grid that ran on 100% renewable power.

Sadly, this reminds me of a debate I had with a colleague several years ago. He was arguing that we should use batteries for grid energy storage, and I countered that they’d be too expensive and would run into severe raw material constraints. I argued for pumped storage, and he countered that the US was unwilling to engage in such large civil engineering exercises any more. Unfortunately, both of our counter-arguments were correct.

Without adequate energy storage, we’ll never get to a grid that is predominantly renewables-based. Combined with our unwillingness to embrace nuclear, this means we’ll almost certainly fail to achieve the desired 80% CO2 reduction on our electrical grid. And likewise, Jack Lifton has essentially shown that an 80% CO2 reduction in our transportation system is infeasible.

At this point, I honestly don’t see how we’ll ever reduce overall CO2 emissions by 80%. For all of our sakes, I hope that the “lukewarmers” are right.

You make the case for increased *conservation* of energy: LED lighting replacing metal-halides (60% energy reduction); weather insulation and day-lighting in home design (40%); walkable/bikeable urban design (?%).

It’s not ALL about electric personal cars.

It doesn’t have to be. The difference is roughly four orders of magnitude, so even if a very tiny fraction of grid storage comes from lithium batteries, we still run into a serious resource constraint.

Anyone who believes we can operate our current societies on 100% renewables (or close to it) is either lying or has been duped.

It is precisely for that reason that we must drastically reform our societies and economies. Industry must be limited to needs, not wants, produced items must be durable, easily recyclable. Relative to the status quo we must all live far simpler lives, though these need not be more impoverished ones and properly done would in fact be richer.

The technology exists to do this now. What does not exist is the technology to continue living the way that we do. Such technology may not ever exist, certainly not on any timeline that matters to those living now. The sooner enough of us to actually make a difference realize that the better.

We find ourselves in a progress trap. We can still escape, limit the damage, but this avenue does not remain open indefinitely.

Interesting read on the Chinese economy.. it doesn’t sound like anything new, just rebranding of the olde European mercantile policies.. without calling colonies what they are.

Mr Young,

You’re preaching to the choir, and I couldn’t agree with you more. Today”s leaders who can’t change a faucet control handle gasket are the absolute slaves of any technology. It’s all magic to these intellectually lazy fools. As Heinlein said, “Any sufficiently advanced technology will seem like magic….” For the “elites” that bar is set very low indeed.

Jack Lifton

Mr. Lifton,

I have more homework to do, but I tend to look at hands on people who have a lot of experience. Jay Leno uses CTEK Smart chargers that also desulfate batteries, friends with motorcycles have a wide range of experience with Battery Sustainers (but with most just knowing they work where others don’t). Optima sells Chargers that seem as functional as fancy looking as they are, but I’d try to see what the experiences are with the K1-Speed electric Go Karts, to see if they are really simple to use, or if there are ways to optimize their use (and avoid problems many wouldn’t expect).

One of our Aeronautics students was a retired Electrical Engineer that specialized in battery portions of emergency power for hospitals, etc, so he is one I would look to for those types of batteries.

If one wants a sample of the electronic control being done for the smart Li-Ion batteries, one can look at a smart battery pack control chip.

One example is the BQ40Z50 from Texas Instruments and is embedded in some Li-Ion smart battery packs, perhaps even the laptop’s battery one is currently using..

These parts are quite sophisticated and even incorporate a “Black Box Event Recorder” to record some events prior to a permanent failure.

This part controls charging via communication with an external smart charger, limits discharging, balances the cells within a pack and disables the pack when failure conditions are met.

The BQ40Z50 is programmed by the battery manufacturing company per the characteristics the battery company chooses.

Here is a link to the 244 page, yes 244 pages, Users Guide on the Texas Instruments website.

http://www.ti.com/lit/ug/sluubc1c/sluubc1c.pdf

In my view, there is a lot of effort going on to extract as much value as possible from batteries, both at the battery manufacturers and semiconductor houses.

It was Arthur C Clarke actually..I know a minor quibble.. although Clarke has less issues with women roles in his novels than Heinlein.

“Any sufficiently advanced technology is indistinguisable from magic….”

And you are correct.. 99% of people don’t understand how a smartphone works.. and most of the top “elites” only care to keep the game running..

It’s worth mentioning that none of the significant elements discussed in this article is in the list of the 20 most abundant elements in the Earth’s crust.

https://en.wikipedia.org/wiki/Abundance_of_elements_in_Earth%27s_crust

Nickel is the 24th most abundant element in the Earth’s crust, followed by copper at number 26. Cobalt is 32, and lithium is 33. None of these elements is rare, like gold or the platinum group metals, but they aren’t common, either.

The younger generations are shunning the suburbs.

Why? So they can walk, take the bus, and not drive.

They know they cannot afford a $50,000 new car, mortgage, Healthcare, Student Loans and taxes.

Will Mr Dickens please pick up the house phone!

MANY of these problems can be solved by well developed (FUEL cells= Hydrogen) technology! Currently only Germans,Yanks, and Japanese are just beginning to sniff the possibilities. Batteries may be regarded as out of date clunkers, if that happens.

“By contrast, free market capitalism has today been almost totally financialized. Its purpose has become the transfer of money to a few, not the creation of new wealth in the financier’s home country through building factories and creating jobs.”

Yes. The ever higher DJIA stocks aren’t “eating sardines”, they’re “trading sardines”.

Thanks for this post.

adding:

“I also note in passing that the USA does not have sufficient domestic lithium refining capacity, not to mention mining capacity to deliver to Tesla 14% of next year’s total global lithium production. And China is well on the way to monopsonizing global lithium use for electrified motor vehicles’ batteries.”

Throwing money at Chinese manufacturers won’t change this dynamic. US politicians and manufacturers may figure this out, eventually. Maybe.

@flora

“Yes. The ever higher DJIA stocks aren’t “eating sardines”, they’re “trading sardines”

Or, in today’s “magical” free market reality, they’re trading in a infinite number of sardine derivatives that don’t, or won’t ever actually exist.

Let them try and “eat” infinite derivatives!

The author glosses over – “Of particular interest today is that China’s rulers have now determined that they must electrify personal as well as mass transportation on the ground in order to eliminate an unforeseen (by them) problem: massive air pollution in their mega cities caused by the concentrations there of fossil-fueled vehicles (which in the general scheme of things globally produce only two percent of “pollution,” but their concentrations in cities are principal contributors to it in those locales).”

“unforseen (by them)” or can you say ignored. These pollution problems have been known since the 50s The author also ignores the rest of the shortsighted ignoring of pollution occurring in China. He also ignores the massive ignoring and non enforcement of existing regulation that would curb pollution In China.

I have read articles 5 or more years ago warning about China’s attempt to control rare Earths. The West has lackadaisically ignored the problem It is more an indictment of the present Western financialization of the the economy than the merit of the Chinese. The new Chinese dynasty of the families of the “heroes of the revolution ” has its own failings. Mao Ze Dong was a great revolutionary but a lousy Emperor. At a meeting where it was brought up that the small communes worked well but the large ones did not, No. 2 Deng Xiaoping said, “black cat, white cat, if it catches mice, it’s a good cat.” Mao like the idea of big communes so Deng was out. The new dynasty has its own shortcomings. Bad investments creating ghost cities and overproduction of steel and …. The stifling of individual initiative through advanced technological surveillance and control of its citizens (that sounds familiar)

Lead acid batteries like that were in the EV1 don’t burn. They can explode due to hydrogen gas build up and an ignition source, but there is nothing to burn in a LA battery. Certain chemistries of Lithium can explode or burn or both while others such as Lithium Iron Phosphate don’t do either. But they are more expensive to make and don’t have the power density of the others.

Great article.

The question is, who is going to buy these cars in the west? Who are they producing them all for if wages have been stagnant for 30 years?!

1. New cars aren’t bought by the average family, used cars are. The affordability question is tricky!

2. In California ZEV credits serve as a hidden subsidy, because at present each electric car earns (from memory) 7 credits, which allow the sale of 7 large SUVs without tripping over CARB emissions regulations. That’s why the Chevy Bolt first went on sale in Colorado. Sales of ZEV credits are the only reason Tesla has been able to report a profit, and even then in only 2 quarters since its accounts became available. If each credit is (currently) worth a few thousand dollars, then you can lower the price enough to put it in reach of well-heeled individuals who want to parade in a “green” vehicle (which is also fun to drive) and still break even. Not if you’re Tesla, they’re a manufacturing disaster, but Chevy turns out the Bolt and the Sonic on the same line in Michigan, ditto the Renault Clio and the electric ZOE in their plant outside Paris.

3. That still leaves a fairly small market, one totally dependent on subsidies. The Chinese government has already pared those back, and sales of standard sedan electric vehicles outside cities with big local subsidies are effectively nil. The battery of their promotion policy has no charge. And they have no more access to cobalt than anyone else – it doesn’t come in veins, it’s a low-grade biproduct of extracting other metals.

Well said

Also, what about the pollution from the production of these batteries? I doubt anyone in the west would like that in their lands. So I think many would be happy for production to be outsourced to China.

Is there any analysis in the reduction of these minerals in batteries? Replacing cobalt with graphene or something. Or simply using less?

Also, are super capacitors dead as battery competitors? I wonder if articles like this will make people invest in such research.

> CWCC has transferred enough wealth from the west to the east to ignite self-sustaining growth in China’s GDP.

That’s hardly fair. Our elites helped!

Interestingly, China may well be landing on what Marx mused about back in the day.

Because he didn’t foresee a top down economy like the USSR, but one that used much of the supply chain built during capitalism, where you didn’t have a few fat cat industrialists and bankers running the show, instead the factories etc were owned by the workers working there.

Yes, well said.

But really this is an old story, and not unique to China at all.

America following Hamilton’s “American System” until around 1970 (ish). Modern Japan. Post-WWII South Korea. Bismark’s Germany. A capitalist system leavened with the regulation and direction of intelligent and patriotic leaders has always been the hallmark of rising industrial powers. Laissez-Faire, rule by people for whom personal greed is the only metric, of declining ones.

Why batteries at all? Why roads? We are steering 4,000 pound objects along 12′ wide lanes made of petroleum and gravel at a mile a minute and slaughtering ourselves at a rate of 37,000 a year. It is ridiculously energy intensive, both in terms of propulsion energy and embodied energy in the vehicle and road bed.

Ultra-lightweight vehicles on ultra-lightweight rail beds could run off of grid power directly and nobody would crash.

We have to edit 90% of the mass out of the system to make it sustainable.

Here come come and efficient hydrogen batteries.

https://patch.com/california/livermore/lawrence-livermore-scientists-extract-hydrogen-water-fuel-source

Lawrence Livermore Scientists Extract Hydrogen From Water As a Fuel Source

Lawrence Livermore scientists have developed a technique that helps extract hydrogen from water efficiently and cheaply.

This article and the earlier one by Yves conclusively shows Tesla will not be able to reach thier battery goals due to lack of raw materials.

Clearly the variables will need to change – smaller batteries and shorter range, or different types.

So many points, so little time. Hey bob, you out there? I got my straw men and circular logic coming, although I have been busy busy in sub sub Reddit world so my referencing and points should stand now, but, you’ll tell me if they don’t!

First as I pointed out in my last cobalt posting post (the previous one) I don’t get these cobalt related threads one bit. I’m sure ya’ll will help me. It may take a few days so I hope you’re patient – my handlers limit my interwebs time. (Yes bob you’re right I am insane)

It would be good I think for Mr. Lifton to work through his maths a bit with us on cobalt. But, even before we get to his maths the chart he provides shows one cathode technology which is in an EV (but maybe not a 300 km EV) which has no cobalt, only manganese and other low cost stuff. And the other cathodes also have different stuffs in different amounts and different availabilities, so, can a Li-Ion battery be manufactured without cobalt and installed in an EV that goes maybe even 300 km? But, maybe that’s not the point?

Maybe the point is that we need more ‘national’ planning (like having an energy plan) like they do in China? Or, like maybe Trump wants to push with coal and not cobalt?

If this gets past both my handlers and onto the NC page I’ll be ecstatic! And, then have I lots more stuff I want to discuss including Mr. Lifton’s earlier response to Vlade where he raises the topic of magical thinking!

Cheers

I suggest you familiarize yourself with our site Policies. Your comment is high on invective and personal attack, which is a violation. Moreover, you make unsubstantiated drive by accusations (the math reference). If you are going to go there, you need to make a claim and support it. You don’t. So I am being generous in letting your comment through. You need to shape up if you are going to comment here. This is not a chat board and the reason we have a high caliber comments section is that we have rules and we enforce them.

Finally, Lifton REPEATEDLY addressed your main issue. Both battery and auto maker lead times are very long. I was looking at these same technologies in the early 1990s. Guess what? Just about none are in production. The fact that something can work in a lab does not mean you can make the battery cheaply and safely enough.

Oh, and BTW in the early 1990s I called correctly that nickel metal hydride batteries would flop, as Lifton in his footnote pointed out they had. So I do have a track record here.

I am assuming your comment flagging me is getting published in the comments with my post which you have tagged as a violation of the NC site policy? And, so, is this response getting published in the comments?

My math reference was not intended to insult, it was a question, although I can see how it could be considered rude. The included chart nor Mr. Lifton’s post allow the reader to determine how he calculates the cobalt mass in Tesla’s battery. The primary point in my flagged post is that Mr. Lifton’s chart includes a battery in a production EV which has zero cobalt in the cathode, and, which leads to the valid question why the focus on cobalt when you can build an Li-Ion battery without cobalt in the cathode. Which is the opening question of my flagged post, which I can no longer see.

I do not think you or Mr. Lifton have adequately addressed my point from your previous post as the example provided as the electrified future is only one option which will meet the criteria of all the jurisdictions which are setting regulations for ‘new energy’ vehicles. Which was in the prior cobalt post comments, but, may have been missed due to my posts being called out for circular logic and straw men. Plug ins with much lower ranges and include internal combustion engines will also meet their criteria. So the proposed 60 kWh battery used for Mr. Lifton’s analysis is not the nominal design which will be built or sold based on the 2040 regulations as set today. In addition, as noted in Mr. Lifton’s chart other EVs are sold which have 0 cobalt.

There are additional points and claims in Mr. Lifton’s article which I believe are questionable and in fact did want to point to discuss.

While you may have called correctly called NiMH batteries as I flop, I use them almost every day. And, you can still buy them new, and, as pointed out in the comments I think they are still in the hybrid Prius. While they won’t be in plug in EVs there are other profitable markets where they are utilized. Times change technology improves, the regulations set for 2040 will not drive the example Mr. Lifton has used and it does not have to do with lead times.

BTW I love Econned

I can get Lifton to address your question but he’s repeatedly said the auto industry has significantly if not overwhelmingly moved to lithium-cobalt batteries. Those vehicles are getting consumer acceptance. Having invested to pursue that approach, automakers won’t change course until there is a tech that produces a big enough improvement in their costs or consumer performance to induce them to change. Given the investment costs and organizational inertia, the improvement would need to be very large, and even so, the implementation time is not trivial.

Re NiMH, my comment related to its use in EVs. NiMH has significant memory effect. If you don’t drain the battery fully or close to fully, it won’t take a full charge. Repeated less than full charges also shorten battery life (you run more cycles with lower total output). Given the high cost and difficulty of dealing with an EV with a dead battery, consumers would be loath to run them down to close to empty before recharging. And NiMH batteries don’t recharge quickly either.