By Jerri-Lynn Scofield, who has worked as a securities lawyer and a derivatives trader. She now spends much of her time in Asia and is currently working on a book about textile artisans.

Several news outlets picked up on a Bloomberg story last week, touting the benefits of burning H & M clothes rather than fossil fuels to supply a Swedish power plant.

As Bloomberg reports in A Power Plant Is Burning H&M Clothes Instead of Coal:

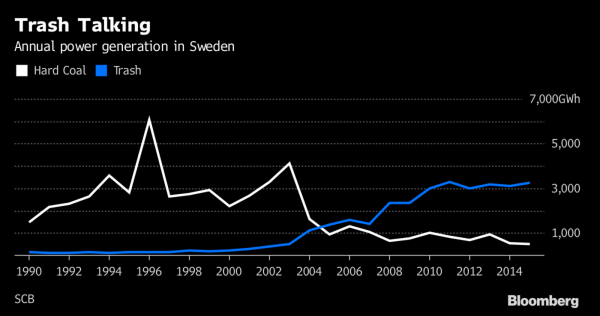

Burning discarded clothing from retail chain Hennes & Mauritz AB is helping a Swedish power plant replace coal for good.

The combined heat and power station in Vasteras, northwest of Stockholm, is converting from oil- and coal-fired generation to become a fossil fuel-free facility by 2020. That means burning recycled wood and trash, including clothes H&M can’t sell.

“For us it’s a burnable material,” said Jens Neren, head of fuel supplies at Malarenergi AB, a utility which owns and operates the 54-year-old plant about 100 kilometers (62 miles) from Stockholm. “Our goal is to use only renewable and recycled fuels.”

Source: Bloomberg

H & M– a major fast fashion player that has taken some steps toward sustainability– was at pains to make clear that the clothes sold to the power plant were defective. Again, according to Bloomberg:

“H&M does not burn any clothes that are safe to use,” Johanna Dahl, head of communications for H&M in Sweden, said by email. “However it is our legal obligation to make sure that clothes that contain mold or do not comply with our strict restriction on chemicals are destroyed.”

This initiative seems to be a twofer: it reduces reliance on fossil fuels, and disposes of waste– the latter a huge and growing problem, as made clear in this recent Washington Post piece, Drowning in garbage, discussing waste disposal in six major cities, Jakarta, Tokyo, Lagos, New York, Sao Paulo and Amsterdam.

To tease the latter issue out further, I’ve written before on the The High Hidden Costs of Fast Fashion, especially to the environment. So, burning these items is probably better than dumping them on third world consumers– where they have disrupted domestic textile markets, at the expense of local economic activity and employment. And it’s also an improvement on burying them in landfills, where they contribute to global warning by generating methane– both points I discussed further in the piece cited above.

But, that doesn’t mean that using clothes– defective or as they may be– to fuel power plants is costless.

For starters, making these clothes consumes fossil fuels, as well as often consumes massive amounts of water. Moving away from fast fashion– and other wasteful consumption patterns– toward more sustainable practices, appears to be a necessary step toward mitigating climate change.

Additionally, as Oilprice.com reports in Sweden Burns H&M Clothes As Fuel, clothes and other non-fossil fuels are shipped from countries, to the Swedish plants– thus no doubt requiring the use of fossil fuels to transport this “waste”. A further problem is that the burning clothes generates its own waste– that includes hazardous components, which must be disposed of in landfills:

As of 2013, Sweden was importing rubbish from other countries in order to feed its hungry waste-to-energy incineration power plants. Each year the Scandinavian country imports 80,000 tons of garbage, mostly from Norway, to fuel homes and businesses. Norway pays Sweden to take away its excess refuse. Sweden then burns it to create electricity and heat, and then sends the ashes left behind by the incinerated waste, and which contain many highly polluting toxins, back to Norway for disposal in a land fill.

Note that the transport of the incinerated waste back to the country of origin itself consumes even more fossil fuels. This environmental cost will likely increase, as Sweden looks farther afield for fuel for its incinerators. Again, according to Oilprice.com:

Catarina Ostlund, the senior advisor to the Swedish Environmental Protection Agency, believes that a new country should be used to provide the extra garbage needed. Norway itself is already very clean, with its own developed recycling sector. She suggests to Public Radio International that “instead we will get the waste from Italy or from Romania or Bulgaria, or the Baltic countries because they landfill a lot in these countries. They don’t have any incineration plants or recycling plants, so they need to find a solution for their waste.”

Way Forward: Circular Economy, and More Emphasis on Reducing and Reusing

As I was compiling today’s Links, a couple other approaches to waste disposal caught my eye. But before I mention those, I want to point readers back to another post I wrote earlier January of this year, Waste Not, Want Not: Right to Repair Laws on Agenda in Some States, which discusses the EU’s more comprehensive approach to waste management, focussed on its circular economy initiative:

One element of this is an ambitious ‘circular economy’ package. Proposed in 2014, The European Commission in May 2015 launched a public consultation on this initiative for increasing resource efficiency, and adopted the package in December of the same year. This policy was motivated by a conscious decision to replace the ‘take-make-consume-dispose’ model of how resources are used and consumed (with some minor tweaks to promote for end-of-life-cycle recycling for some inputs). EU policymakers appreciate that as the world’s population approaches 9 billion people, the prevailing wasteful linear model of resource consumption results is no longer sustainable. The circular economy alternative instead considers the entire life cycle of a product, and seeks to reduce waste by various means, including reducing materials used in products; promoting durability and thereby extending the useful life of a product; practicing ecodesign (and so facilitating easier maintenance, repair, or remanufacturing); and promoting waste reduction by minimizing recycling costs and encouraging reuse.

That post delves into the circular economy model in greater detail, so I’ll not repeat any more of its points here. But the key takeaway is that the problem of waste disposal– and some of the related issues of climate change due to overconsumption– would be greatly mitigated if the EU approach succeeds and is adopted more broadly beyond its borders.

The Way Forward?

I’ll close with two small recent developments that provide some small cause for optimism. First, at the very small-scale level, I noticed the following puff piece in The Independent, Zero Waste: Inside London’s First Plastic-Free Shop:

But Ingrid Caldironi has taken matters into her own hands by opening the city’s first plastic free shop. Bulk Market stocks more than 300 items in the pop-up shop and it’s not just food. Alongside dried goods there’s bamboo toothbrushes, paper-wrapped toilet roll and even dog food.

“The idea came from my own needs. I wanted to support the right businesses and be able to shop without creating any waste, but there wasn’t anything like that in London,” says Caldironi.

“I always thought waste was a natural output of modern living, but it turns out to be poor design. Things aren’t designed in a circular economy mind-set yet,” she adds.

Now, not to be overly pedantic, but it surely overstates the case to call this London’s first plastic-free shop– as shopkeeping certainly flourished in London long before this shop was created. And I’m not so sure how unique nor innovative the notion of bulk purchasing, and refillable containers is in today’s UK. I remember, while a student at Oxford in the mid-80s, refilling containers at the Body Shop, for example– and I also remember that company’s use of special plastic bags that it claimed were designed to disintegrate.

Also, other how shops catered to students on a tight budgets by selling foodstuffs, to order, in small quantities, rather than in large prepackaged amounts. Less stuff meant less waste– something to bear in mind as food waste is a major driver of the landfill crisis.

Another piece I highlighted in todays Links, This Guy Makes Money Off Your Cigarette Butts and Flip-Flops discusses more ambitious approach TerraCycle founder Tom Szaky is taking to waste management:

Now he’s seeking millions to help fund a bigger mission: making trash the star of a circular economy, where re-use is the norm. Inspired by the glass milk-bottle porch deliveries of yesteryear, he’s creating a durable consumer-recycling system. Think shampoo encased in gleaming stainless-steel capsules, ice cream packaged in thermos-like containers, coffee sealed in metal pods instead of plastic — all the packages to be carted off, sanitized, deconstructed and used again.

I remember well when products such as milk were delivered in reusable glass bottles– again, harkening back to my student days in Oxford, and even before that, in the ‘60s, when a milkman delivered milk to our house in Sparta, New Jersey.

Szaky’s plans go well beyond milk, however, and this and similar initiatives will be necessary if we’re to defeat the scourge of disposability, especially our reliance on single-use plastic and other wasteful packaging.

..true..however new renewable tech does exist:

https://www.scientificamerican.com/article/new-concentrating-solar-tower-is-worth-its-salt-with-24-7-power/

meanwhile, trump’s fossil fuel EPA administrator has removed from internet, all info pertaining, coming from EPA scientists…

Thanks for this- I think this kind of technology is the wave of the future as it directly addresses the chief drawback of intermittently available solar power generation and turns it into a load balancing asset.

Another way to do the same thing is to follow Denmark’s example and utilise the batteries in the country’s fleet of electric cars for the same propose; charge while the sun shines and wind blows, then draw down when demand exceeds supply. This approach is still less efficient than doing it at the generation station, due to battery losses, hence the potential importance of this type of solar facility.

Is there a way to get the word out to people like my niece, who see having a new outfit to wear (almost every time I see her) is a good thing? How do we compensate for the propaganda the fashion mags throw at these kids every day? I wish we had the wisdom of our elderly imposed upon our youth. Perhaps a program to mentor? I don’t know the answer.

Perhaps a Slow Fashion movement in the spirit of the Slow Food movement. Make Slow Fashion groovy and cool for some people. Maybe some people will turn into just enough people spread the coolness and groovitude of Slow Fashion to widening circles of people around them.

There are already young people who shop for durable clothes in “Vintage Clothing” stores . . . which are different than Thrift Stores and Salvation Army Stores. So perhaps they are a base to begin building a Slow Fashion movement out from.

Recently helped a kombucha brewing worker co-op get up and going in Missoula, MT. They’re using reused beer bottles and hoping to set up a regular bottle exchange program at a few of the local grocery stores.

A year ago or so, all the Montana micro-breweries agreed to start using a standard bottle. Bayern Brewing, in Missoula has a bottle-washing/label removing machine that they’re using to provide pallets of clean, re-used bottles to Back to the Mother (the co-op) at a lower cost than new ones. So BttM is keeping trash out of the wastestream, and getting themselves a better mark-up while at the same time being able to be competitive on price…and what makes it possible is the fact that all the breweries agreed to standardize in order to make empty beer bottles an easily usable resource. Which is just to point out that cooperation on multiple levels is what really allows these sorts of things to thrive. We need not just individual enterprises working on this stuff, we need an entire ecosystem geared towards waste reduction/re-use/recycling/up-cycling etc.

Thats a fantastic idea.

Years ago, when craft brewing was just started, I bought a bottle locally from the first Dublin craft brewer, from a plant just 5 minutes walk from my home. When I looked at the bottle it said ‘brewed in Dublin, bottled in Dusseldorf’!

I did ask them, they said there was nobody local willing to bottle small quantities from casks, so they had to arrange to get it done when at a German beer festival.

I am a member of a CSB (Community-Supported Brewhouse) here in Tucson. If you’re a member, you’re expected to drink the beer, enjoy it, then return the bottles to the brewers, who are a husband and wife team.

They just started the CSB in October and are already expanding production. They’ll be opening to new members at our December beer release party.

Cool. Do they have a website?

Not yet.

I think that the team was surprised by how successful their little venture has been. They’re still working on the marketing side of things.

I can’t understand the logic of manufacturing a single use glass bottle. The commercial energy costs that enable melting tons of sand an hour 24/7 at over 1000 degrees F must be astronomically cheaper than what I use to keep from freezing all winter keeping the air in my house at 62 degrees. There could be a half dozen bottle forms to cover all uses, yet the recycling platitude we satisfy ourselves with is transporting them to be crushed as ‘clean’ garbage. The deposit penalty of $0.05 hasn’t changed in over 30 years and our state exempts non-carbonated beverages from the penalty so it’s basically a carbonated beverage use tax to discard them which has produced a huge pool of money, which is managed differently by each state Bottle Bill Revenue I remember as a child it was $0.10 before becoming $0.05 – with inflation, it should be at least $0.25 each or a packaging surcharge added to each purchase across the board.

Very good comment. When I was a kid, well over 50 years ago, we got 5 cents per bottle. That must be what, a dollar now? And the bottles were not recycled, they were reused, IIRC. “Recycling platitude”, love it!

I am old enough to remember when beer and soda was sold mostly in returnable bottles. My dad was a working class guy who bought his favorite beer by the case and returned the lot- case and bottles -to local liquor store. To my recollection, the heavy cardboard case seemed to hold up over time through repeated use- they always seemed pretty banged up. But then again, it was the beer that was important, not the case. Todays marketing is mostly about the packaging, not the product.

This return to local manufacture and reuse is a good sign, and inevitable.

A thrift store in Visalia had a 4 for a dollar book sale a couple of weeks ago and I snatched up $6* worth in a frenzy of too many Danielle Steele novels and Christian oriented tomes (this is the CVBB, after all) in between, when it struck me that the thicker ones were certainly worth more than 2 bits in energy, may 451 degrees be the final chapter?

* the prize being 3 thick volumes of HL Mencken’s The American Language, from 1937.

Its a surprisingly difficult topic. I can’t find it online now, but years ago I saw a transport supply chain for the recycling of a plastic bottle to a factory in the Irish midlands which made polartec fleece jackets from 100% recycled plastic. The bottle may have been put in a recycling bin across the road from the jacket factory, but it went on a huge loop around Britain and Ireland to different factories for various processing stages. It may well have used less energy to have just shipped it to China for processing.

Likewise, quite a significant amount of Irish recycling waste was sent to Sweden, precisely to be processed or incinerated in one of the plants in the article. The total environmental impact of the shipping was sometimes calculated as less than just trucking it across Ireland to a similar plant. So ‘distance’ isn’t necessarily a proxy for appropriate treatment/disposal of waste. You have to look at the entire production cycle to be sure you are doing the right thing, and somethings this produces surprising conclusions.

Even a fairly simple product – recycled newsprint – can be more efficiently incinerated in some circumstances. I once visited a paper pulp factor which extracted 20% of the lowest quality paper sent in which was then burnt to power the recycling process. They were reluctant to publicise this because of the fear it would be portrayed as ‘fake recycling’ or ‘incineration by the back door’ or whatever.

Recycling clothing is a really difficult issue. The process of separating the different materials and finding appropriate re-uses is very complex and expensive. The only really suitable environmental option is to buy as little as possible, and buy quality when you can, and keep that item of clothing useable for as long as possible.

I knew a fellow who used old clothing as a raw material to build a large ranch complex out in New Mexico’s desert, where wood was quite expensive. He’d build frames, drape them with chickenwire, and then dip the old clothes in a thin cement mixture; layering the cement-soaked rags over these chickenwire structures created incredibly strong solid surfaces – kind of like paper-mache. This was many years ago – but I just searched on youtube and it’s apparently a full-scale industry now. (Nat Geo).

This is similar to a line of thought of mine, to use the clothes as insulation and packing material. We use tons of new plastic and paper for packing.

Re: recycling clothing – I have memories from my childhood (in England) of my grandma “pricking mats” – making a rug or mat for the floor using old woollen or other fairly heavy material from old coats, jackets, trousers, the material was cut into strips – oh, about an inch and a half wide and 4 inches long, then attached to some kind of fairly solid sacking using a tool – I guess it was called a pricker – just a polished piece of wood, sharpened down to a point at one end. I’d be encouraged to help in these endeavours. Gran had such a rug, with simple design using different coloured pieces, in front of her fireplace for many years. These mats were heavy though, and a hassle to clean.

It’d be difficult to find used clothing materials of sufficient quality and longevity these days to recycle in that way.

In India, worn-out textiles are reused. Weavers in Shantiniketan incorporate old textiles into the weft to make khesh, a handwoven fabric formed into saris and household fabrics. A weaver in Gujarat I know employs a similar technique to make rugs.

In Bengal (now divided between India and Bangladesh), women traditionally layer saris and old dhotis to make kantha quilts. Top lawyer is stitched, creating fantastic stitch paintings. Some of these quilts are hundreds of years old and are now found in museum collections.Kantha: The Embroidered Quilts of Bengal from the Jill and Sheldon Bonovitz and the Stella Kramrisch Collections

My mother used to do almost the same. She would get old wool coats from thrift shops and friends, take them apart, cut them into strips, sew the strips together and make braided rugs out of them. I used to do the same with selvages you could buy from Pendleton Woolen Mills. Only I wove them into rag rugs. Don’t know if Pendleton still sells the selvages. Boro from Japan and Kantha from India are other ways of using old clothes. When my mother was a nurse on Saipan during the Second World War, a friend of hers got married and my mother made the wedding dress out of parachute silk!! Seems it was during the 80’s that all this cool reusing of things fell by the wayside, except for us old hippies! Now I notice more young people are sewing and knitting, God bless them, so maybe it will all come back. Hope so, it kind of has to.

Used clothing from resale shops is almost always higher quality than new and far cheaper.

And eBay, but buying clothes on eBay is more hit or miss.

Yes I have found that too, but the better quality stuff is draining away slowly but surely as crapification creeps in, even there.

This is a main problem with global trade under neoliberal rules – which include international capital mobility; thus H & M can set up factories anywhere in the ‘free trade zone’ – such as Myanmar (where it uses 14-year olds as cheap labor) and ship the clothes around the world without worrying about trans-national capital taxes, European or American labor and pollution laws, etc.

Notice also that the article mentions ‘mold’ on the clothes – a constant problem, since these manufacturing zones are humid environments in the tropics, and the path from factory to shop is very long. Thus, the clothes are all sprayed with formaldehyde to prevent mildew and mold during shipping. They are also individually packaged in plastic, which all ends up in landfills in the destination country.

The result is low prices for consumers, but the clothing doesn’t last very long – and the vast loss of jobs in the domestic garment industry is another part of the equation. For example, all the upscale outdoor clothing companies – Patagonia, North Face, etc. – used to have factories in the California Bay Area, high-tech factories – all shut down and offshored to cut labor costs, a move made possible by neoliberal free trade decisions.

You can still find local manufactureres here and there – you may have to pay three times as much for their clothing, but the tradeoff is that the construction quality is much higher and the clothes last much longer; you’re supporting local economic activity and there are no long-distance shipping emissions involved.

As far as burning clothes – well, the dyes and formaldehyde raise issues, it could be like a toxic waste incinerator, with a nasty emissions profile.

Worse yet are “anti-bacterials” mixed right in with the plastic used to make the fibers that the cloth is made of. Basically you are wearing pesticides, or are brushing your teeth with pesticide tainted plastic toothbrushes or are changing your baby on a pesticide dosed plastic changing table.

“Anti-bacterial anything” against your skin or in your immediate environment is bad IMHO.

In researching family history, I purchased a will from 1805 and the will makes plain that clothes of the deceased were to be given to certain people. It was treated as if it were solid material assets along with furniture. As it was a high status family I am assuming that they would be of good quality but the point is that clothing was once considered valuable enough so that it was used repeatedly. Unlike the one-season durability of clothing now, these clothes lasted.

A deceased neighbour who worked in the mill in England told us she was still using the clothing and materials she brought out from England in the 1970s as it lasted so well and so long unlike the newer stuff. Even as far back as the middle ages a pair of leather shoes could be expected to last a century being passed down the generations to those to whom it would fit. Burning clothes for fuel sounds like, to this jaded soul, as merely another way of virtue signalling by justifying the purchase of this seasons one hit fashion wonders while being environmentally conscience.

so, i’m also reading this on my feedreader not twenty minutes later:

Fashion Industry Report: One Truckload of Clothing Is Wasted Per Second

Thanks for your comment. Reports such as this one are issued periodically, but don’t really get the play they deserve, and not nearly enough people are aware of how much the current take-make-dispose fashion cycle contributes to global warming. Although I’ve posted several times on this topic, I expect I’ll incorporate this report into my next post on this topic, so I especially appreciate you drawing it to my attention.