By Lambert Strether of Corrente

Readers, I have purchased Obama’s latest autobiography, along with the complimentary handtruck needed to take it home, and now I’m going to have to pull on my yellow waders and read it, as much as I can stand. So that post is coming, but that post is not this post, so despite my proffered tempation, please don’t hijack the comments section to talk about [genuflects] Obama. You can do that in Links or Water Cooler. The topic of this post is sand.

And what a topic it is! In all these posts about the biosphere, I begin — all too obviously — by knowing nothing, and try to allow what I discover to shape the post. But in my reading I have never encountered a topic that serendipitously connects such wildly disparate topics as Grenfell, the Mekong, and of course Covid vials (here, here), all of which have been covered at Naked Capitalism. Sand did this, whether from necessity or chance I do not know.

So what is sand? From Geology.com:

The word “sand” is actually used for a “particle size” rather than for a “material.” Sand is a loose, granular material with particles that range in size between 1/16 millimeter and 2 millimeters in diameter. It can be composed of mineral material such as quartz, orthoclase, or gypsum; organic material such as mollusk shells, coral fragments, or radiolarian tests; or rock fragments such as basalt, pumice, or chert. Where sand accumulates in large quantities, it can be lithified into a sedimentary rock known as sandstone.

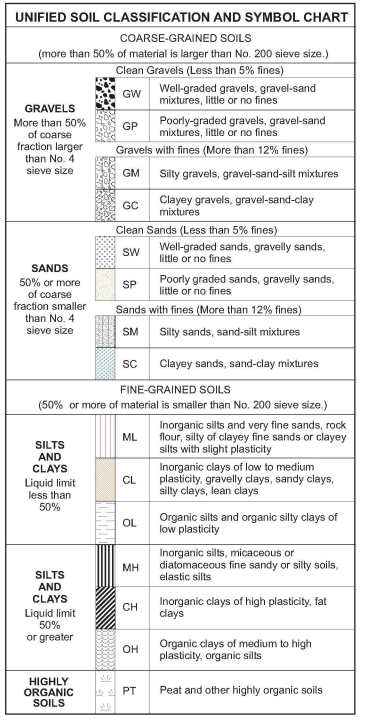

We classify sand by the size of its grains, as for example in the Unified Soil Classification and Symbol table:

(I’m including the whole table because I think it is neat. It also mentions peat, superhero of the biosphere, just covered at NC here.) It’s also possible to use more fine-grained categories, as “very fine sand (1⁄16 – 1⁄8 mm diameter), fine sand (1⁄8 mm – 1⁄4 mm), medium sand (1⁄4 mm – 1⁄2 mm), coarse sand (1⁄2 mm – 1 mm), and very coarse sand (1 mm – 2 mm).

How do we classify sand? Not by the materials from which it is made, which is perhaps good, because history is not easy to classify. From Nature, “What is Sand Made of? History“:

Sand is possibly something you take for granted; it gets in your hair and your clothes and all over your food at the beach. But sand is also fascinating. Sandy beaches are dynamic: sand accumulates slowly over time, travels down the coast with longshore drift, is removed from the beach by large waves during storms, and can be redeposited back on the beach from offshore banks during calm periods. Sand is typically made mostly of varying amounts of material weathered from inland rocks (or seacliff material) and transported to the beach on the wind or in rivers, and/or shells and other hard parts precipitated out of the ocean water by marine organisms. Sand therefore records processes at a variety of timescales. Looking closely at sand under a microscope, we can determine the mineral or organismal composition of the sand and determine where it originated, and what kind of rocks or organisms created the sand.

When I was a child, I spoke as a child and also loved sand. There were two kinds: The fine-grained sand at the ocean or from a river bed, brought to me by my father for my sandbox, both good for building. And there was the sand at the lake, trucked in to make an artificial beach, coarse-grained and not good for anything. This childhood distinction corresponds to the commercial distinction between SIlica Sand and Regular Sand. From Shaw Resources, “What Is Silica Sand & How Is It Different From Regular Sand?”

Silica sand, also known as quartz sand, white sand, or industrial sand, is made up of two main elements: silica and oxygen. Specifically, silica sand is made up of silicon dioxide (SiO2). The most common form of SiO2 is quartz – a chemically inert and relatively hard mineral…. In order to be considered a silica sand the material must contain at least 95% SiO2 and less than 0.6% iron oxide. If the sand does not meet this criteria, it will qualify as what’s often called ‘regular’ sand.

Regular sand, also known as feldspathic sand, brown sand, or construction sand, will always contain some silica, but only in amounts less than 95%. For example, typical brown sand used for concrete applications can contain up to 80% SiO2, along with varying amounts of iron, carbonate, potassium, and other trace elements/minerals. These ‘impurities’ make regular sand more chemically reactive and often darker in colour when compared to silica sand. The color for non-silica sands (regular sands) can be various shades white, pink, green, and black as well – depending on the geological makeup and geographic location of the sand deposit.

As an aggregate of identical small grains, “Sand Found to Flow Like Water“:

When poured, sand behaves much like water to form water-like droplets, scientists have discovered.

Hence, desert “sand falls”:

Stunning Sand falls.

Amazing views filmed by a Bedouin in the northern deserts of Arabia.

He says it's the first time he sees it.#Saudi pic.twitter.com/WZn5pUAW7S

— Muna AbuSulayman منى (@abusulayman) November 22, 2020

Now that we know something about sand as a substance, let’s turn to why we might be running out of it (or least the silica sand that we use to make new cladding for Grenfell tower, could mine from the Mekong, or could heat and shape into glass vials to distribute Covid vaccines. I’m sorry to turn into a supply chain romantic, but that seems to be where we are.) First, we’ll look at demand; then, we will look at supply; and then we will look at the the effects in particular industries.

Looking first at demand, from the BBC, “Why the world is running out of sand“:

How can we possibly be running low on a substance found in virtually every country on earth and that seems essentially limitless?

Sand, however, is the most-consumed natural resource on the planet besides water. People use some 50 billion tonnes of “aggregate” – the industry term for sand and gravel, which tend to be found together – every year. That’s more than enough to blanket the entire United Kingdom.

The problem lies in the type of sand we are using. Desert sand is largely useless to us. The overwhelming bulk of the sand we harvest goes to make concrete, and for that purpose, desert sand grains are the wrong shape. Eroded by wind rather than water, they are too smooth and rounded to lock together to form stable concrete.

The sand we need is the more angular stuff [silica sand] found in the beds, banks, and floodplains of rivers, as well as in lakes and on the seashore. The demand for that material is so intense that around the world, riverbeds and beaches are being stripped bare, and farmlands and forests torn up to get at the precious grains. And in a growing number of countries, criminal gangs have moved in to the trade, spawning an often lethal black market in sand.

“The issue of sand comes as a surprise to many, but it shouldn’t,” says Pascal Peduzzi, a researcher with the United Nations Environment Programme. “We cannot extract 50 billion tonnes per year of any material without leading to massive impacts on the planet and thus on people’s lives.”

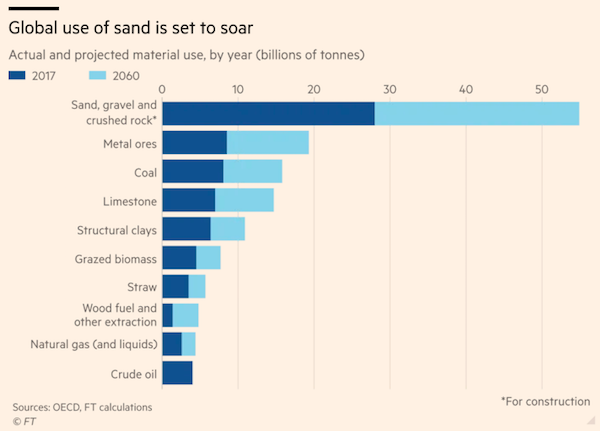

The Financial Times provides a chart on future global demand:

As you can see, Peduzzi’s “massive impacts” can only be expected to increase, both for beaches and for rivers.

For impacts on beaches, R. Young and A. Griffith, “Documenting the global impacts of beach sand mining,” European Geosciences Union:

Currently, we have documented sand mining in 35 countries on 6 continents representing the removal of millions of cubic meters of sand. Problems extend from Asia where critical infrastructure has been disrupted by sand mining to the Caribbean where policy reform has swiftly followed a highly publicized theft of sand. The Program for the Study of Developed Shorelines recently observed extensive sand mining in Morocco at the regional scale. Tens of kilometers of beach have been stripped of sand and the mining continues southward reducing hope of a thriving tourism-based economy. Problems caused by beach sand mining include: destruction of natural beaches and the ecosystems they protect (e.g. dunes, wetlands), habitat loss for globally important species (e.g. turtles, shorebirds), destruction of nearshore marine ecosystems, increased shoreline erosion rates, reduced protection from storms, tsunamis, and wave events, and economic losses through tourist abandonment and loss of coastal aesthetics. The threats posed by sand mining are made even more critical given the prospect of a significant rise in global sea level over the coming decades.

Coastal Care has a case study, “Mining Of Coastal Sand: A Critical Environmental and Economic Problem For Morocco“:

Mining of coastal sand bodies has gone on for as long as humans have lived near the shore. Initially it occurred on a bucketful scale and at a local level. Now it occurs on the scale of long lines of large dump trucks containing more than 10 cubic meters of sand each. As humans have devised more efficient ways to remove large volumes of sand and as shorefront development has simultaneously increased, coastal sand mining has become a major global problem. We believe that at the present time, the most extensive mining of onshore coastal sand in the world occurs in Morocco…

Here is what happened to one beach:

The rocky layers that once were buried in sand replace dunes. The dune ecosystem is completely gone. Back-dune vegetation is dying because it is no longer protected from salt spray and wind by dunes. Wetlands are at risk because of sand and salt intrusion. The coastal road to Tangier will occasionally be flooded and perhaps even eroded in places in future storms due to the lack of protective dunes. The beach will not experience normal storm recovery because of the lack of dune sand and erosion (shoreline retreat) rates can be expected to increase significantly in future years. Present and future buildings constructed to get a sea view will be endangered in future storms.

For impacts on rivers (skipping over the Yangtze) we can look at the Mekong. From the BBC, “How the scramble for sand is destroying the Mekong“:

The entire ecosystem of this South East Asian river is under threat, all because of the world’s insatiable demand for sand.

“Extraction is happening at absolutely astronomical rates, we’re having an industrial-scale transformation of the shape of the planet,” says river scientist Prof Stephen Darby at Southampton University.

His studies on the lower Mekong show its bed has been lowered by several metres in just a few years, over many hundreds of kilometres, all in the quest for sand.

Turning from demand to supply, these impacts have led many countries[1] to limit export of sand. From the Financial Times, “Boom in global sand trade fuels fears over conservation“:

The construction industry’s use of sand, gravel and crushed rock outstrips total global consumption of all fossil fuels and metals combined, when measured by weight, according to the OECD. It forecasts that in the next four decades construction demand for sand and gravel will almost double to cater for the world’s growing population and rising living standards.

As demand mounts for sand, a growing number of countries, mostly in south-east Asia, are seeking to protect their resources by banning or significantly restricting exports.

Indonesia banned marine sand exports in 2003 and four years later extended this ban to include sand extracted from land and rivers, too.

Vietnamese miners were instructed to stop exporting sea sand in 2010.

Cambodia brought in a temporary ban in 2016 and then fully banned exports in 2017.

Malaysia was the first to introduce a ban, as early as 1997, but it was lifted in 2015. Then, after almost 55m tonnes of sand made its way to Singapore in 2018, the Malaysian government reintroduced the ban earlier this year.

The supply of sand is also limited in Europe, although the dynamic there seems not to be regulation but land use. From Deustche Welle, “Not enough sand for construction industry despite abundance?“:

Some 99% of all sand and gravel deposits in [Germany] are not where the building material can be easily accessed, because the land above it is used differently. Elsner explains you cannot excavate anything in the country’s large nature reserves and wetland protection areas. Nor can you use the areas that have already been developed.

In addition, low interest rates often stand in the way of exploiting a potential sand or gravel pit. Many landowners think it’s not a good idea to sell their plots to sandpit operators. Instead, they hope for land prices to rise further and get more money out of it.

Given extremely powerful demand, and increasingly limited supply, we can see that not every customer is going to able to get the product they want from the supply chain in the quantity or quality they might like.[2] From Stockhead, “The silica sand demand storm is coming and Australia is preparing to face it head on“:

Even medical vials used to store vaccines are in short supply and while the actual tonnage required for their production is relatively minute, they still require silica sand of extremely high purity.

And while demand for such high-purity silica sand is rising, supply is increasingly becoming an issue to the point that illegal mining is a problem in some countries, while China has included it on its list of strategic minerals.

There is also growing demand for silica sand to produce engineered stone cladding.

[VRX Silica managing director Bruce Maluish] noted that in the wake of the 2017 Grenfell Tower fire in London, there has been a strong push to replace the flammable external cladding that was widely blamed for the rapid spread of the fire with other materials including engineered stone.

It would not have occured to me that vaccinating as many people as possible against Covid could possibly contradicct protecting people in towers with flammable cladding like Grenfell from being burned to death, but here we are[3]. On sand and medical vials, from The Institute of Supply Management, “When Bottles (as in Medical Vials) Become the Bottleneck”:

With billions of dollars being spent for a coronavirus (COVID-19) vaccine, it could seem that all will be well once a viable one is found. However, even then, many people might still not be able to access it — a shortage of glass vials is predicted to create a bottleneck for the vaccine’s delivery.

Medical vials are made of Type I borosilicate glass. Another type of borosilicate glass — soda-lime glass (Type III), which is used for windows, house decor and glass bottles — cannot be used for vaccine vials due to its chemical reactivity and its lack of resistance to thermal shock during the vial manufacturing process. Type I glass has better pH stability, it releases less alkali and chemicals, and it is more resistant to drastic temperature changes than Type III glass, making it the gold standard in vials making, according to an article in The Medicine Maker.

In the short term, it seems that the current shortage is due to slow growth of the vials manufacturing industry combined with an unexpected surge in demand. The glass-vial industry is heavily capital-intensive due to the cost to acquire the equipment. Another consideration: The equipment consumes a lot of energy — the furnace used to melt the sand, for example, runs at close to 2,000 degrees when no vials are being made. Additionally, special requirements like precision details, manufacturing process control, level and intensity of quality checks lead to additional cost. Combined, these factors create a high barrier of entry, and it could be risky to invest in the industry without a promising perspective of sales.

In the long term, experts say the shortage will be driven by the lack of a core ingredient: sand. Though there may be plenty of sand on the planet, not all of it is usable for glass vials. The type suitable for making Type I borosilicate glass is silica sand. Containing large amounts of silicon dioxide (SiO2), the resulting glass is chemically inert. As the concentration of SiO2 increases, so does the clarity and strength of the resulting glass. Silica sand is also used in construction (concrete, shingles and mortar) and in the technology industry (computer chips).

Sands such as silica sand are highly sought due to their jagged shape that can grip better, unlike desert and beach sands that are eroded into smoother grains by the wind. Most silica sand is found in river beds and lakes.

From Dezeen magazine, “Sand becomes ‘increasingly scarce and expensive’, threatening glassmaking and construction“:

[British geologist Michael Welland] described the fine sands commonly used to make glass as “a good example of an exhaustible specialty sand whose availability is unsustainable,” but said it is “impossible to quantify” how much remains in the world.

“Perhaps [there is] 20 years [supply] of the known high-purity glass sand deposits, but more will be found with increasing difficulty and expense,” he said.

Of course, Southeast Asia, where Malaysia, Vietnam, and Cambodia could supply sand if they would, has a rich tradition of local operators who can smooth away tiresome bureaucratic obstacles. So it may be that the supply is greater than we think. Nevertheless, Dezeen concludes:

A symposium taking place at Dutch Design Week later this month will discuss the rapid depletion of the world’s sand reserves, which could leave supplies of the high-quality sand used in the glass industry exhausted within 20 years.

The “sand crisis” threatens to destabilise the global glassmaking and concrete industries, with the latter using an estimated 25 billion tons of sand and gravel every year.

Conclusion

It would seem that, as for so many biosphere problems, some sort of global mobilization is needed. From Global News, “How the world might run out of sand“:

Mobilizing a sand agenda

An important starting point for mobilizing a sand agenda is the 2019 UNEP sand governance report, focusing on accountability and transparency in sand value chains. Global sand governance is critical.

Changing how we build our cities is another part of how we face the sand and climate crises. We need to ask ourselves why we have been so seduced by concrete. If we do not change our habits, and encourage the development of “green concrete” and alternative building materials or innovations such as using bacterial species in bio-concrete, the world built from sand may be pulled down by its own weight.

To further mobilize a sand agenda, researchers and campaigners could focus on narratives that draw on the climate crisis or other ecological dimensions, such as directing attention to how sand dredging is linked to landslides and poorer water quality, or how sand infill leads to the loss of wetland habitat.

Others could unpack labour regimes, advocate for better working conditions, or explore the involvement of political groups in financing sand extraction. We need to delve deeper into how the sand mining sector relies on cheap labour, fast-moving money, some of it illicit, and criminal activities.

This sand agenda, through the consideration of working conditions and ecological dimensions, enables us to imagine a global future that is greener.

“Tis a consummation devoutly to be wished!

NOTES

[1] But not the United States; we are the world’s top exporter of sand.

[2] Sadly, I will not be able to look at fracking sand, which is just as important a chokepoint for keeping oil in the ground as pipelines.

[3] As it turns out, medical vials and stone cladding compete with frack sand as well. From Metal Bulletin, “Growing US shortage of sand for foundry and glass industries“:

A leading industrial sand supplier in Wisconsin told IM: “Industrial sand is selling extremely well across the US due to the ongoing boom in oil and natural gas drilling. As a result there is now a shortage of silica sand for other industries like foundry and glass which are steadily recovering”.

That quote is from 2011, and the fracking industry has gone bust again, so I felt it was simpler to leave fracking out.

Interesting–probably a lot more than Obama’s latest opus.

Perhaps these medical vials can be recycled

Much more than the medical vials can be recycled.

“Glass recycling is gaining popularity all over the world owing to its astounding benefits. Glass can be completely recycled over and over without any loss of quality or purity content. The raw materials required for the production of glass are silica, soda ash, limestone, cullet, etc. … Recycled glass can substitute around 95% of the raw materials used in glass production… Additionally, the introduction of recycled glass during production can help glass manufacturers to cut down on energy costs and furnace maintenance & repair costs.”

https://www.gminsights.com/industry-analysis/recycled-glass-market

Thanks for this! Very interesting

Amen to all sands not being equal. During the Iraq occupation the US military had to build a buttload of blast walls. These concrete barriers needed sand for the concrete but the type of sand found in Iraq was not up to the job. So the US military at great expense found itself importing shiploads of the stuff from the United Arab Emirates and Qatar. The logistics on those blast walls were horrible-

https://atwar.blogs.nytimes.com/2010/03/31/iraq-the-wrong-type-of-sand/

Your willingness to take one for the team, and actually immerse in Obama’s insipid and self-congratulatory exhalations, is appreciated.

yessssss. Presumably you already had some hand sanitiser to apply after handling the tome?

to the topic at hand, I read a good New Yorker article a few years ago: The World is Running Out of Sand

As a geotechnical engineer in B.C. I am blessed by a cornucopia of granular products that can be ordered up relatively cheaply courtesy of the last glacial period. Materials that are routinely dug up and replaced here would be considered valuable in their own right as fill in other parts of the world or one province over.

I remember a highways job in Alberta where the summer students were put to work tending the clay fill so that it would be the right moisture condition to be placed and compacted. And it had to be summer students. That sort of material cannot be placed in an Alberta winter because it freezes, or a B.C. winter for that matter because it rains too much. But in the right parts of B.C. you can obtain obscene quantities of aggregate at a very good price. Several years ago I priced a job that had quarry sand barged in and installed for around $7 a ton. As soon as you have to haul material in trucks it gets far more expensive; they need loading and unloading and that usually involves an excavator at one end if not both.

It is not just about sand. There is a big range of granular products which require coarser fractions. Sand makes good bulk fill but a blend of sand and gravel is needed for concrete, asphalt, road base, structural fill, etc. Sourcing this can be challenging depending where you are and what rocks and geological processes have modified them locally.

P.S. The chart above is for soil classification. It does not directly characterize the grain size distribution. See https://pubs.usgs.gov/of/2006/1195/htmldocs/images/chart.gif

> The chart above is for soil classification. It does not directly characterize the grain size distribution.

Thanks, I love classification charts. (I did address grain size in prose, but this is much better).

It is indeed a fascinating topic, and far more complex than is often appreciated. One thing you don’t touch on is the issue of fracking, which uses very large quantities of specialist (high quartz) sands. Because of the high value of these sands, it was worth trucking them across the US (the cost of transport is a major constraint on sand availability).

Another issue you don’t mention is the legacy of the ice age. Across the northern hemisphere the biggest source of high quality sand is fluvioglacial deposits – those beautifully clean deep beds of sand left behind by glacial lakes or overflows. Mining for these has destroyed fascinating remains from the ice age, such as the eskers which snake across many landscapes from Ireland to Montana, along with kames and outwash plains. The latter were often very low fertility so became common land for grazing and have often been accidentally protected because they were enclosed for recreation or military use before anyone realised how valuable the sand was beneath them. The Phoenix Park in Dublin is one, and the Curragh is another – the latter will be familiar to many as it has often been used for filming battle scenes, from Henry IV to Braveheart. On the subject of filming, the beautiful eroded quartz sands of Wicklow will be familiar to fans of The Vikings tv series, as the inland beach of Lough Tay stands in for a Norwegian Fjord (its featured in numerous films, no doubt the gleaming sand is a big draw to location managers).

Unfortunately, regulatory issues often make finding alternatives to sand difficult. A particularly annoying one is the difficulties in using Pulverised Fuel Ash (from power stations or incinerators) for construction purposes. For some uses, it is actually better than sand, but nervousness among construction managers about including ‘waste’ in their material means they are reluctant to do so, and industry is often unwilling to invest in the maturing process required to make is safe. Hence you often have the stupidity of PFA being dumped in the holes created by mining sand – you will often find this around major coal power stations. PFA is also often used in land reclamation (especially in Japan), which is environmentally much worse as it is more likely to leach than if it is incorporated into concrete.

Another underused resource is construction waste. When the landfill tax was introduced in the 1990’s in the UK it was very successful at persuading industry to invest in crushing and re-using concrete and brick rather than use virgin materials. While its not suitable for high value concrete, its perfectly useable for foundations and other less structurally critical applications. But again, its often an issue of regulation – construction managers just find using certified virgin sources easier to deal with.

There are some alternatives to excessive use of concrete. Engineered wood is one, although of course that has its own issues, and I think there is a reluctance to use wood in hot, high humidity climates for obvious reasons. But more investment in this is certainly needed to diversify the sources of building material.

Some sources are relatively benign. In Taiwan one time I was astonished to see a line of about 50 trucks at night, snaking along the huge (maybe a mile wide) riverbed of one of the many flood channels that cut through the mountains. Every year the Typhoon season dumps a massive amount of material into these beds, constantly replenishing supplies. Trucking it along the bed saves eroding the roads. I’ve no idea if its all domestically used or exported, but they certainly have a lot of it.

> One thing you don’t touch on is the issue of fracking, which uses very large quantities of specialist (high quartz) sands.

See [2] and [3], where fracking is (barely) touched on.

I wish I could have gone deeply into the geology of sand formation, and also its behavior as a liquid. (There’s a reason the tipping point metaphor uses a sandpile.) I had to leave Martian sand on the cutting room floor:

Truly an amazing substance!

Sorry I missed those comments Lambert! I was reading before I’d finished my first morning coffee.

Incidentally, the main use for very high quartz sand before fracking was for military uses (ultra hard concrete for bunkers) and…. aquariums. The only suitable source for frack sand in Ireland (back before they banned exploration) was a tiny sand quarry that supplies those aquariums you see in Chinese restaurants. The quartz is the lovely shiny part.

Sand flows are indeed beautiful – I was fascinated by them as a child digging into rain hardened sand dunes on the west coast of Ireland (the rain would form a crust, holding back loose sand – as it dried out, with a little help from my hand the sand would flow out like a river). This is a beach experience those people used to sand dunes in nice sunny climes miss out on (that, and goosebumps in July) . I’ve also seen them flow like mist down the side of sand quarries when the sun hits wet sand at the side of fluvioglacial beds. Semi-compacted sand has a curiously sensual tactile quality.

I’ve been photographing dune erosion on a stretch of southern Maine beach since the summer, and if I haven’t taken the time so far to find out what’s causing it, that’s about to change. The erosion process is as beautiful in its way as the sand flows in western Ireland must be, with gorgeous sculptural qualities and fragile root systems exposed by the process.

Here’s one: https://www.instagram.com/p/CH6OW9TrH-q/

And related: https://www.instagram.com/p/CGWFLfPsMdI/

Maybe Lambert will see fit to augment the daily plant in Water Cooler with a Mineral of the Day.

Euurgh, I posted a reply, and it vanished. Apologies if this turns out to be a double post.

Sand dune formation is fascinating, and there is a lot we don’t know. I don’t know if its online, but I once saw a gif like clip of the movement of Bull Island in Dublin Bay over about 50 years, as measured by aerial photos and maps. The sand spit is 5km long and was formed by harbour works in tehe18th Century (designed by Capt. Bligh, no less). The island seemed to flutter in the current, like a Buddhist votive ribbon, but each flutter took several years.

Coastal dunes are of course highly dynamic structures, as the soon to be former POTUS will tell you (‘Local Golf Course Owner Loses Election in the US’ as the local newspaper put it). His Irish golf course is on a dune system, and he and his consultants have been fighting a futile battle against nature and climate change.

Fluvioglacial features are also fascinating, and they are frozen in time by vegetation. Seeing one sliced through for road works or extractions can be like reading a book – you can see carefully in the layers all the rapid changes during those crazy few hundred years of deglaciation, when hundreds of thousands of years of ice accumlation was released in a few short bursts. Anyone under the illusion that climate change is a gradual process should observe and learn this lesson. When the climate changes, the results are brutal and change the very fabric of the earth we live on.

Some dune systems seem to defy all modelling – one are the giant dunes in the Badain Jaran desert on the China/Mongolia border. They are huge, and seemingly semi-permanent. My guess is that they are ‘rooted’ to place by water seeps. I once fell off one, closely followed by a camel. Fortunately, sand is soft and the camel was more surefooted than me.

Thanks for a beautiful post! For sheer grandeur, do not miss the Great Sand Dunes National Park and Preserve in Colorado. Dunes 700 feet high serve to properly teach humans a lesson in humility. Of course, those lessons never take.

“there is a reluctance to use wood in hot, high humidity climates”. In New Orleans, which surely qualifies, the local cypress has been used for house building for centuries. Since it’s native to the marshes, cypress can tolerate high amounts of moisture, from either air or water, without rotting.

Interesting to note that at one time New Jersey was the center of glass making for the US. And in later years the industry worked hand in hand with the pharmaceutical industry located in that area.

The prehistoric dunes of the Pine Barrens were the primary source of sand for this glass making industry.

Sand mining is sometimes very contentious here in Michigan, and generally not permitted along beaches. I’ve seen operations in Muskegan and Ludington, one an old inholding in a large state park. It is a high quality silica sand and desirable for glass making. However, and especially along lake Michigan, vast tracts of the dunes environment are, and continue to be, protected. Both sand and gravel are mined, inland, in the massive glacial moraines that make up Michigan, which takes pressure off any lakeshore mining. However, there are still fights. Locals by me are fighting a gravel pit at the headwaters of a particularly nice stream when there is a glut of aggregate available in the state.

I am fortunate to live near the Sleeping Bear Dunes National Lakeshore. These are massive perched dunes sitting atop a moraine rising 450 feet above the lake. They are breathtakingly scenic with varied recreation (lots of human-powered silent sports here). No sand mining here with over 100 miles of protected coastline in the region.

Lambert, its not related to this topic, but the previous one on peat, but you might be interested in this link:

Cabinet approves 108 million euro for Midlands Peat Restoration.

Its not clear to me if all that money is going to the peat bogs themselves – I suspect a lot of it is aimed at compensating/redeploying workers in peat harvesting. Restoring the bogs themselves is very cheap and easy – you just need to block up the drains and let nature take its course. Its important that the remnant peat not be allowed dry out further as this results in ammonia run-off which is quite damaging to extensive areas of watercourse.

Its worth pointing out though that its been led by the government agency that destroyed them in the first place. They are open about having plans to re-use the lands for wind and solar farms, waste treatment, and other uses. No doubt they’ll be trying to blend these in with their existing plans, although I see no reason why allowing rewilding would not be compatible with building wind turbines.

Incidentally, the main reason the peat burning plants are shutting is that there is now so much wind energy in the country they make no sense, even for base power. Some of the plants will still have an operational capacity for peaking power and transitional storage (i.e. the existing power infrastructure will stay in use, even though the thermal plants themselves will close).

Just saw this at a Canadian site, sharing it for is obvious relevance to this discussion: “Concrete is everywhere. It’s also terrible for the planet”

Thanks Lambert, very interesting.

Another big, and growing, user of silicon dioxide sand are solar panels:

https://www.cleanenergyreviews.info/blog/solar-panel-components-construction

Scroll down to “Manufacturing crystalline silicon cells”. It appears that crushing quartz rock and purifying it can yield high quality sand.

This graph is the Wentworth classification system used by geologists and geomorphologists in sedimentology.

The previous chart you showed up top is the Unified Classification System developed in WW II and early Cold War to help with construcitng airfields etc. https://apps.dtic.mil/dtic/tr/fulltext/u2/a026473.pdf

Different uses end up with different classification systems.

One of the reasons that there is a shortage of sand is that much of the sand is actually buried in “mud” (actually a technical term indicating a number of grain sizes in a mixture). That would require sieving, washing, cycloning etc. to generate clean sand necessary for a lot of uses. So you need to get sand from defined energy systems that sort the sand and separate it from other things. So rivers and beaches are common systems that have zones with well-defined repetitive energies that create mineable deposits. If the sand moves into estuaries etc where there is a rapid decrease in velocity, then everything, including silt and clay, gets deposited at the same time as “mud”. Then you have to wait geologic time for currents to move it into environments where it can be sorted and deposited on beaches as sand.

Awesome! Thanks! What a lucid description:

Rather like blogging!

Attn Lambert:

https://www.sciencedaily.com/releases/2020/11/201102110010.htm?utm_source=newsletter&utm_medium=email&utm_campaign=newsletter_axioscities&stream=cities

Recently read the book “The World in a Grain.” Highly recommenced if anyone wants a deeper dive into the world of sand. A dark one indeed especially in places like India where the black market for the right kind of sand is a billion dollar industry.

Geologist here-

I’ve been fortunate enough to make a decent living working in various aspects of this field, sand, so thanks for the article and resulting discussion.

Sand used for fracking is exactly the same sand used for glass making- barely cemented, high purity silica sand with grains that are rounded. Fracking uses the larger grains, glass makers prefer the smaller grains. It’s exactly the same stuff. If you have driven the bluffs along the Mississippi in MN, IA, and IL, the yellow, white, and black sandstones of the Jordan and St. Peter sandstones, Tunnel City Group, and the Wonewoc and Mount Simon formations you see on the bluffs are the biggest sources of silica sand in the USA. The rounded grains make this sand challenging to use in concrete, although it’s ideal for use as filter material. Funny fact- this valuable material is used for cattle bedding. Literally a waste.

I could go on for hours about sand (complete with pictures!), so I’ll stop before I succumb to the temptation to do so.