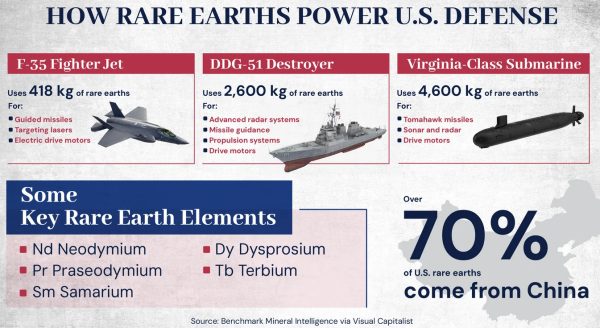

Rare earth elements (REE) are at the core of modern military power. Embedded in jet engines, precision-guided munitions, radar systems, and advanced communications, these materials enable capabilities that give the United States military its technological edge. In a sustained crisis or great-power conflict, disruptions in the REE supply chain could ripple through U.S. defense production, slowing or halting critical programs. Securing access to these materials is therefore not just an industrial policy question but a matter of national security.

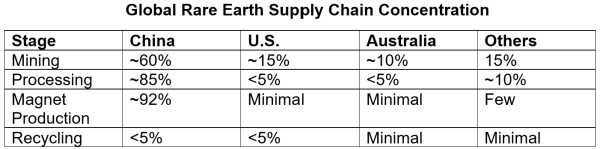

REE are a small group of metals with extraordinary magnetic, thermal, and electronic properties that make them indispensable to modern military technology. The global supply chain for these materials is highly concentrated, with the People’s Republic of China dominating mining, processing and magnet production. Recently, China has retaliated against U.S. import tariffs by restricting exports of REE. This article describes the role of REE in weapons production and the foreign policy implications of controlling their supply

Rare Earth Elements: Why the Military Needs Them

There are seventeen rare earth elements. Their unique combination of magnetic strength, temperature resistance, and optical characteristics makes them essential to modern weapons systems. REEs underpin many of the most sophisticated defense systems, from jet engines to precision-guided munitions. While many are abundant, they are difficult to extract and process. Few nations have invested in the costly and environmentally challenging refining processes required for their use at scale.

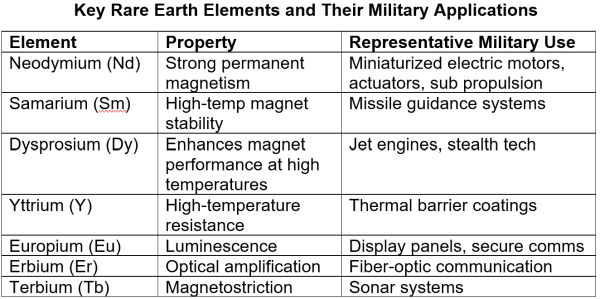

Rare earth elements permeate every domain of modern warfare. They are essential to the performance, efficiency, and stealth of advanced systems. Their strategic value lies not only in their technical properties but in their irreplaceability in critical applications. The table below links key REE materials to their military applications.

Strategic Competition and National Security Implications

Rare earth elements have become a geopolitical lever. In the context of intensifying U.S.–China competition, control of processing and magnet production represents a critical vulnerability for Western defense industries. Management of REE supply has become an integral component of national security strategy.

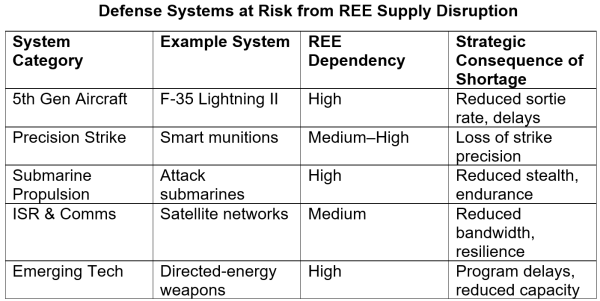

Supply Chain Vulnerabilities and Strategic Risks

Although REEs are mined in several countries, China accounts for most of the world’s refining capacity and magnet production. This concentration creates a single point of vulnerability for defense industrial bases worldwide. China’s recent REE export restrictions have demonstrated the strategic leverage this confers.

Rare earth mining – It’s a big job

Rare Earths in China/U.S. Trade War

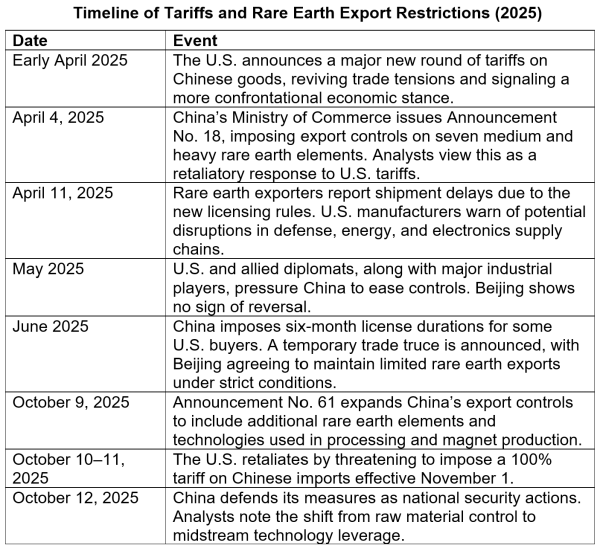

When the Trump administration increased tariffs on imports from China this year, China retaliated by restricting exports of REE. The following table describes the development of this trade conflict.

The timeline illustrates how a conventional trade dispute can quickly acquire strategic weight. The U.S. tariff escalation in early April prompted a targeted Chinese response in the form of rare earth export controls—an area where Beijing has significant leverage. What followed was a series of reciprocal moves that broadened the dispute from tariffs to critical materials and industrial capacity.

By October, China had extended its controls beyond raw materials to processing technologies, signaling its willingness to use supply chain dominance as a strategic tool. The U.S. countered with tariff threats, framing the issue as a matter of national security. This sequence underscores how critical mineral supply chains can serve as instruments of geopolitical influence, turning what might appear as an economic disagreement into a contest over technological and strategic advantage.

Policy Responses and Supply Chain Diversification

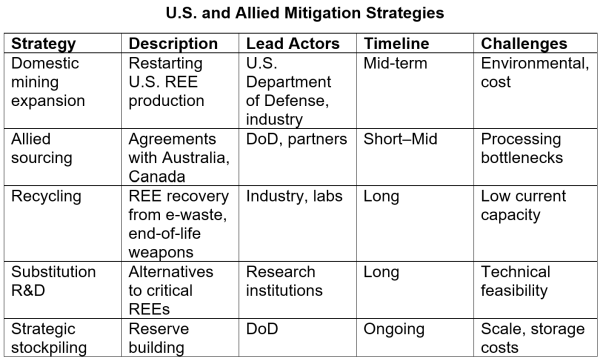

The U.S. and its allies have begun to address REE vulnerabilities through a combination of domestic production, allied sourcing, recycling, substitution research, and strategic stockpiling. These initiatives are long-term undertakings but are crucial to maintaining technological superiority.

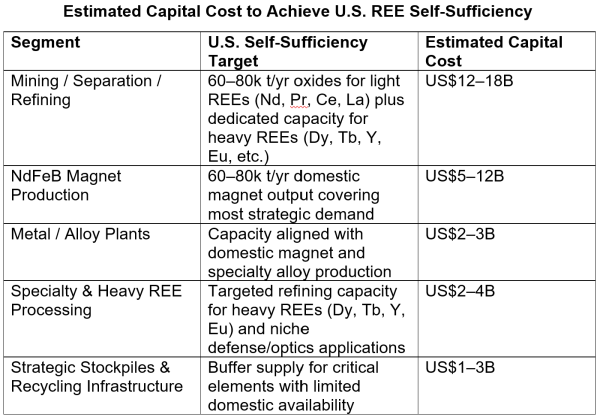

Achieving full U.S. self-sufficiency in REE, covering both light and heavy elements as well as specialty uses, would require an estimated $22–40 billion in capital investment over approximately 7–12 years. This includes building sufficient mining and separation capacity to meet domestic demand for light REEs such as neodymium, praseodymium, cerium, and lanthanum, while adding targeted capacity for heavy and specialty REEs like dysprosium, terbium, yttrium, and europium, which are essential for defense, aerospace, and advanced optics. Additional investment would fund NdFeB magnet production, metal and alloy plants, and stockpiling and recycling infrastructure to buffer against supply shocks.

Defense Materials Autarky?

While the cost of establishing U.S. self-sufficiency in rare earth elements is substantial, on the order of tens of billions of dollars over a decade, rare earths are just one critical input among many required to sustain a modern defense-industrial base. Achieving true defense materials autarky would require massive investments across many other foundational sectors: semiconductors, energetics, specialty metals, shipbuilding, advanced composites, precision manufacturing, and power technologies.

The U.S. defense industry relies on an estimated $125–210 billion per year in foreign-sourced materials, components, and systems concentrated in a handful of strategically critical categories such as semiconductors, advanced electronics, rare earths, energetics, specialty metals, high-end machine tools, and shipbuilding inputs. These imports are often low in volume but high in supply-chain leverage, meaning disruptions can have disproportionate operational effects.

Replacing these imports with fully domestic production would require building entire upstream and midstream supply chains. On a national scale, this implies capital investments in the low to mid trillions of dollars over one to two decades, along with major workforce expansion and long-term industrial coordination. In short, U.S. defense import dependence is relatively modest in dollar terms but strategically concentrated and costly to unwind, making autarky a long-term, resource-intensive undertaking rather than a rapid substitution.

Achieving defense materials autarky in the United States would require a level of central economic planning and coordination fundamentally at odds with the structure of the U.S. political economy. The scale of investment, sequencing, and workforce mobilization involved cannot be achieved through market forces alone; it demands long-term commitments, prioritized capital allocation, synchronized infrastructure build-outs, and centralized control over critical supply chains. Yet the U.S. system is built around decentralized private investment, fragmented regulatory authority, and short political time horizons, making sustained strategic coordination difficult.

Conclusion

Rare earth elements are an industrial prerequisite of modern military power. They enable the performance and reliability of systems that define strategic advantage. Because REE production is concentrated in the hands of a few foreign producers, they are also a source of vulnerability. Managing this risk requires deliberate investment, coordination, and innovation. The volatile and erratic international economic policies of the Trump administration are at odds with the coherent strategic planning required to build a stable defense infrastructure. Facts are stubborn things, and the economic facts of securing REE and other strategic materials will ultimately determine the course of U.S. trade policy.

I think the timeline is missing the 50% rule that commerce put in before the government shutdown that lead to the October 9 announcements by China. This violated the spirit of the Madrid negotiations

https://x.com/pstAsiatech/status/1976709915067781345

And this has led to the seizure of the Chinese company by the Dutch which was then cut off from Chinese technology and products

https://www.moonofalabama.org/2025/10/china-reacts-after-u-s-pushed-netherlands-to-seize-chinese-owned-company.html

oh please, The so called “West” violates agreements ALL THE TIME when it’s NOT convenient to them. Chyna is simply looking after its own interests. If the so called “Wes” had a monopoly on REE, they would have stopped selling them to CHyna years ago just like they did with chips.

Just as Russians get chips from dishwashers, Americans may need to extract REEs from Chinese televisions.

What’s your response to Doomberg’s claim that it will only take the US 3-4 years to replace the rare earth elements needed for the MIC?

Other sources I’ve heard say it will take decades.

And in the mean time? Existing REE-dependent defense projects are slowed or halted while unexpected problems and delays occur in establishing a full domestic production chain of REE. Once REE infrastructure funds are committed, the government will lose all leverage over contractors for meeting schedule and quality goals. As the article points out, the USA doesn’t do central planning well. Fortress America, with full autarky of strategic resources, is a fantasy that is economically and politically infeasible. Even Trump knows that.

i dont think it’ll ever happen,lol.

1. lack of people who know how to make factories, or the machines that make machines.(are we gonna kidnap chinese engineers on the high seas?)

2….and this is likely the big ‘un): an utter lack of ability for long term and/or strategic thinking among that class of parasites who either run things, or have the wherewithal($) to even begin studying the matter.

i’ve seen this last referenced in these pages and elsewhere repeatedly over the years.

the mirrored bubble those people live in has become ever more hermetic and isolated from th real…and we’re seeing it in evidence with all these chest thumping cheerleaders…as if throwing money at a wild idea will just magically make it so.

the short-termism that has plagued that class for so long has ended up neutering them.

cant think beyond the next quarter, etc.

the USA is more likely to end up an actual plantation economy, exporting raw materials to people that actually build things…all the while boasting in the worker’s lean-to, over their beer/bread ration, about how great we were, but for the (insert various scapegoats) stabbing us in the back.

tent city nation.

it’ll be great.

Facts bro.

But I do see another way to Make America 🇺🇸 Great Again.

The Rich won’t like it of course when we partner with China & Russia in a Grand Alliance to finally end the rein of the Vampire Squids that have been plaguing us since the beginning of Western Civilization.

another disturbing read…idk who linked it:

https://substack.com/home/post/p-176018373

He does not understand how corrupt and ideologically broken the west is at this stage.

Of course not. He likes what he sees in the mirror.

I suspect that he is correct on engineering grounds but as others point out, not on political and managerial grounds.

It’s doable in some platonic sense but not actually doable in reality

This change to self-sufficiency on rare earths would require a change of mind by the globalists, which so far have been wanting to expand the rules based order and at the same time keep costs and taxes low by outsourcing elsewhere. Whether the neoliberal mindset will change timely and find at home the necessary expertise, equipment, etc (at US prices!) is something to watch out. Would military spending skyrocket?

A challenge any modern REE operation is going to have in the US is that these are nasty processes. Fracking, leach pits, and powerful chemicals are combine to get this stuff out of the ground and usable. Where are you going to do that in the US? Who’s water are you going to ruin? For a basic primer, Wikipedia explains what leachate is. And here’s a proposal brief for obtaining Gallium from mining operations in Montana, using still to be proven tech that can only reduce the waste from the process, not eliminate it.

So all we have to do is get the permits, establish a site, begin the extraction, verify new tech works at scale, and contain new waste streams, just to replace the current supplys chain we have for Gallium. Could that happen in a few years? Yes. Is that likely to happen in a few years? No. And we need to do this with a host of elements.

The people coming after Trump don’t seem too much brighter or more focused. Which means in typical American fashion, we’ll manage to get fascists and autocrats who can’t make the trains run on time. Or force through projects like this. I think all current projections about a recovery and new domestic REE development at scales large enough to make us self sufficient are educated wishes.

There’s no way the US will rebuild REE processing to needed levels in that time. I am not even sure the US has the expertise left in the domestic labor pool to do it. The domestic expert metallurgists are long gone and the people they trained to succeed them were mostly boomers who are also pretty much gone.

I was involved with a REE mining project in AZ some years ago and the only options we had for selling the ore was Mountain Pass CA and China. Luckily for us, MP was willing to take it even though ours was monazite (REE phosphate) and theirs was bastnatite (REE carbonate). Even a tiny bit (<10%) of allenite (REE silicate) or thorium would have sunk the deal. Unfortunately for us, Molycorp went bust before we could ship anything and our project wrapped up in bankruptcy.

I don't know of a single heavy REE (HREE) deposit in the US or Canada. HREEs are the critical material for high temperature uses.

As an aside, rare earth elements are not abundant!!!. They are found at parts per million levels or smaller in many common minerals, but that does not make them common at all. I may be getting old, but REE ores were not even touched upon in the economic geology classes i took.

Further, iron and aluminum are abundant but they can’t be extracted from just anything- they must be concentrated into ores. REE also can’t be extracted from just anything but are 1/1000 less abundant than Fe and Al to begin with, and REE ores even more scarce. We were pricing our monazite ore by the pound, not the ton, which gives an idea of both value and scarcity.

i have on my place, well out of the way, and in the bushes, a great pile of copper…mostly old window unit cores, de-gassed.

also have a much smaller pile of old lithium batteries, from various defunct power tools.

dump wont take the latter, and…much like tires, or telephone poles…theres nothing to do with them, save use them for something else…or give them away.

since lithium is an apparently valuable commodity, i chose to save them, like i did with that copper.

copper prices at the salvage yards have yet to get high enough to justify a 160 mile round trip.

now i’m wondering about lithium in all those battries.

a cursory search of the 3 salvage yards i know of turns up nothing.

the city’s “recycling center” will take themk, and then turn around and sell them somewhere,lol.

be cool to bypass the middleman.

anyone know anything?

https://www.call2recycle.org/faqs/

I used this (above) for my battery pack, electric leaf blower.

https://www.tceq.texas.gov/permitting/waste_permits/ihw_permits/managing-electric-vehicle-batteries

Maybe this information will be helpful, about auto, maybe a link in there?

All the best

Yup armed madhouse.

I think the focus on RRE misses the points that there are hundreds, thousands of materials that the US doesn’t make, doesn’t have, doesn’t refine, many/most come from the ever enlarged BRICS countries. RRE is just one.

Take ship building, essentially the US doesn’t build ships. Or antimony which I guess is needed for bombs, US gets it from China. Or the unique steel requirements for transformers, of which the US only makes a small amount and imports the rest and the list goes on and on and on. As an airplane person, the US had to set up shell companies to get enough titanium from the USSR to build the SR71 because we don’t have it.

I don’t think it’s possible to build everything all in house these days. China maybe, US not.

It’s the wake up call for cooperation. But no matter how hard the people in Washington are hit on the head it’s not working.

In short. Has the US the capability for re-industrialization at somewhere near WW2-style mobilization, though may be at a lower scale? Doubtful in current circumstances. If only for the regiments of consultants, advisors, financial magicians, lawyers, etc which seem to be needed these days. With luck, AI saves the day!

The factories that won WW2 have been mostly torn down, with the vast amount of land those facilities required repurposed for retail or housing.

Those factories also left behind significant contamination of air, soil, and water that continues to be a hazard today, long after the factories closed.

The domestic resources necessary to rebuild heavy manufacturing also don’t exist anymore. Iron mines around Lake Superior have mostly closed, the Texas oil that fueled the war machine of the 1930s through 1970s is effectively gone, and electricity is dedicated to data centers and crypto.

Recently read Harry Braverman’s book Labor and Monopoly Capital. In the book he describes the process of Taylorization where the aim is to atomize a production process to individual steps. In so doing the worker is shut out from knowing much about the overall process and purpose. The’re just doing their little function.

The behavior of today’s political rein holders appears as though they have been Taylorized by their insular lives and focused education.

Lenin’s social failure was that he adopted Taylorization in the early Soviet Union. Had he had access to Marx’s The German Ideology (written in 1844 but not published until 1931), he might have better understood the alienation inherent in Capitalism. Thus, it is said that he adopted State Capitalism.

As you question our political rein holders, they are functionaries of the Capital class. The initial point of socialism is a democracy of production. People on the ground must question, discuss and control what is to happen, and how they accomplish it. There may be fragmentation, discord and inefficiency but: people have input and resolution.

The Capital class cannot have that.

Interesting thesis. Thanks!

Socialism leading to communism would be a benign future, if we can evolve, though I don’t adhere to China’s description therein. I lament that I doubt that humanity can achieve a rational worldwide social cohesion, at least before we do ourselves in, along with life on the planet.

Me in 2005 to my (very Marxist) econ professor: So why can’t we just have this?

Prof: consciousness

Thank you so much!

Very welcome Alice!

It was pretty much at that point I gave up on economics/political economy as a productive way forward. I’ve spent the last 20 years working on the consciousness side of the problem.

Tldr version: We are animals evolved to live in tribes who have not (this far) adapted to non-tribal life. We are crippled by trust issues, fear and a pervasive feeling of “unsafe”. We unconsciously divide people into “part of the tribe” and “not part of the tribe”. This evolved model doesn’t work and it’s misaligned with modern life. It’s also exploitable by the Trumps, Farages etc

So I work to help people overcome trauma, feel safe, transcend the evolved conditioning and (hopefully) expand their consciousness to a universal tribe version.

It’s slow work and some days I feel pessimistic; others it feels worthwhile.

But I know (or strongly suspect) that peace and truly loving consciousness is the only way forward.

To this end I’ve recently been doing trauma work with Israelis. It’s hard (and some of it is too much for me to hold space for) but I have in a tiny way changed some haters (and killers) into more peaceful people. I hope they will go home and spread this leave just a little.

Drip by drip we can change the world

I have heard it said that China is administered in [much] the same way it has been for two thousand five hundred years.

I should have said that I would adhere to any one’s broader understanding of China, and specifically, its current administration. I am naught.

The guys at The Duran were talking about the problem of the technologies needed to refine and process rare earths and the consensus is that providing that if everything goes well for countries like the US and nothing goes wrong, that it will take about 30 years too get to the technological point that the Chinese are right now by which time the Chinese would have pulled away even more. You would be talking about research projects, teaching professors that have expertise in this field, graduated students who would be able to find work in this field and even set up their own firms. Can’t see it happening myself.

My SWAG, is it will take a lot longer and a lot more $$ to build from scratch a REE ecosystem. There are no longer any schools teaching REE. I can’t find the link – I recall it was a Kevin Walmsley Inside China Business, but here is a link to one on batteries, same story.

https://kdwalmsley.substack.com/p/why-chinas-monopolies-on-batteries

Basically, there is no educational infrastructure, economic infrastructure, or supporting manufacturing infrastructure for advanced battery manufacturing (not a lab benchtop demonstrator to raise VC funds) — it would take decades to produce highly inferior batteries at unaffordable prices if ( a ginormous if ) a plan could be made, funded, and stuck to for longer than a single presidential term.

He had another good video about the fact we don’t make enough explosives@ tnt , ” high grade cotton” ?( other than gun cotton/powder , i suspect), or the pre-cursers to manufacturing them.

Then throw in the explosives plant in tennessee the other day that leveled one of the factories we do have….

Another aspect of the pipe dream

Gallium is an REE, mainly imported from China. It is mixed into Gallium Arsenide (GaA) or more recently Gallium Nitride (GaN). Both are superior to silicon and have replaced it in uses that endure higher temperatures: think miniaturized radars, and radios for military fighter aircraft. Also, large fixed radar systems as used for long range surveillance and imaging threats.

GaN is better than GaA in “electronically steered arrays” like on the nose of F-22 and in the newest SPY 6 radar for latest version of AEGIS destroyers.

Both China and Russia are far ahead of US in applying GaN to microcircuits!

Will US pay for F-35’s with no radar antenna in the nose?

I second the critical nature of Gallium. It’s used in RF chips and power electronics, and the alternatives have significant penalties in terms of size, weight, and performance.

As far as long-term thinking goes, I just want to note that REEs have been found on our Moon, and procuring them outside Earth’s ecosphere isn’t necessarily a bad thing.

Rare Earth Elements are not particularly rare, and there are sources in U.S. The issue is that their extraction is a nasty and environmentally unfriendly process. Poisonous. Noxious. Nefaste.

Because of the size of their electron shells, elements in the Lanthanide series tend to get shunted aside as materials cool and transition to a crystal. On our Moon they ended up in a rock type known as KREEP: Potassium, REEs, and Phosphorous. Generally it is associated with lava flows, so nowhere close to the poles and all the usual power-cycle challenges are in full effect.

How would we extract it? Good question. I’m personally a fan of high-temperature stuff, and we do have to consider what advantages our Moon’s natural vacuum (far better than we can achieve with our pumps and seals here on Earth) and 1/6th gravity might bring to the table. Simple parabolic mirrors can focus stronger sunlight (no atmosphere to attenuate it) to achieve ridiculously high temperatures. Molten electrolysis of the materials might allow for easier separation. Maybe massive density separation settling tanks.

An easy solution to the REE problem? No. But our Moon is a long-term strategic part of growing the economy in the U.S. We can keep crapping all over our nest, but we don’t have to do so. There is an entire solar system of energy and resources awaiting us. A pathway to mitigating or even decreasing the damage we do to our planet, perhaps even restoring it to a place where children can grow up healthy.

The Moon as a source of rare resources…reminds me of the novel I just rediscovered thanks to the NC commentariat: the Hopkins Manuscript. The story there is pretty grim.

KREEP is associated with felsic lava. Moon rocks are mafic- more Mg and Ca, less K and Na.

I did PhD work on lunar regolith brought back by the Apollos, mainly by Jack Schmitt on 17. There aren’t REE minearals laying around. It’s PPB to PPM level concentrations disseminated throughout the rocks similar to terrestrial basalts, gabbros, and anorthosites. The similarity is so striking that it is one on the key indicators that the moon formed by a homogenizing impact (or two) with proto-earth.

[Responding to Ken Murphy

October 14, 2025 at 10:34 pm]

Given the history of humanity, particularly the last 500 years or so, I think the most likely scenario will be to keep damaging our planet while also damaging the Moon and any other celestial body that finds itself on the path of and accessible to human greed. Sorry if that sounds too pessimistic or cynical.

It does come across as a bit Malthusian, or whatever one would call the philosophy of what I summarize as “Humanity is $#1+ and only does $#1++¥ things, so we should keep humanity here on Earth and it’ll get what it deserves”.

I recently read “Who Owns the Moon” by A.C. Grayling, which covers very little about the Moon but is rather a long diatribe about why going to space will have folks here on Earth at each other’s throats. A rather frustrating read because many of his examples are self-contradictory, as with how the colonial experience in Africa is relevant even though there are no indigenous populations on the Moon or Mars or the asteroids.

Will humans take human problems and human prejudices with them wherever they go? Of course, it’s the nature of the beast, so to speak. But using the 500 year time-frame noted, I would say that an awful lot has been accomplished here in the U.S. Like, every bit of infrastructure, an amazing variety of art and literature, and a civil society that can regularly go beyond our planet into space. Look around you; none of that existed here in the U.S. 500 years ago.

About ten years ago when I lived in Mongolia I got an email from German Public Radio (I was then freelancing for them) to do something about rare earth and Mongolia. Background to all of that was the fact that China had cornered the production of rare earth metals and these were mined mostly in the Chinese province of Inner Mongolia which is geologically very similar to Mongolia. Now the Chinese did the mining and refining but weren´t able to control the downstream process. That is make magnets et al. These were mostly the preserve of Japanese and German companies. So the Chinese threatened to cut off German and Japanese companies from these ressources of they didn´t set up subsidiaries and transferred know-how.

There was panic in Berlin and Tokyo and the scramble for other suppliers was on. That is why there was such an interest in Mongolia. Nothing came of this and neither did I do the piece for Germany but in the course of research I learned quite a bit. Here is what I remember as I don´t have my notes anymore:

very early on, still in the Nineties, the Chinese government identified Rare Earth Metals as a possible wedge to acquire leverage in international trade. As far as I remember it was some descendant of Deng Xiao Ping himself who got the contract to set up the respective mining industry. Back then the most important mine for rare earth metals was in the US. I seem to remember the name as Mountain View and it was in Nevada. The US mine had high production costs because of environmental regulations and was controversial as rare earth mining is an extremely dirty process.

The Chinese who didn´t care about pollution did therefore have no problem unter cutting the US mine and becoming the main supplier of these metals. If memory doesn´t fail me they even acquired the mining equipment of the US main after it was shut down.

But mining and refining is one thing. The other thing is making something out of the stuff. For that they needed German and Japanese technology. So they set about blackmailing various specialist firms in the respective countries. Which turned out to be a mistake. Both Germany and Japan scrambled to develop mines in other countries, to recycle these metals et al. So the Chinese relented before they lost their monopoly. After that I didn´t follow the story anymore.

Seems like by now they have acquired the necessary know-how and possibly control the downstream processes as well. Whatever. The US by herself most likely would indeed take decades to catch up. But teamed up with know-how from Japan and Germany things could change very quickly. But for that you would need a dedicated long term industrial effort. Somehow I don´t see neither the necessary patience nor institutional staying power.

Two addenda: thinking about it again I believe it was 15 years ago when the Chinese tried to blackmail Germany and Japan. Furthermore I believe there is one more very important point: from reading various articles it seems as if the issue is not anymore strictly the supply of rare earth metals but by now already the various down stream products. That is magnets et al. The mining itself shouldn´t pose insurmountable problems. It is what you make out of these metals. To my recollection the US didn´t have any capacity in these areas already 15 years ago. But Japan and Germany had. Certainly the Chinese have the know-how now and maybe even a near monopoly. They did the same thing with the German solar industry. Last week the last maker of solar panels in Germany shut down. Now the Chinese will consolidate the industry and price rises are just a matter of time…

Thank you Tom67. Very interesting background info.

I would caution against using that chart from Benchmark Minerals Intelligence. The numbers they publish, at least for the F35, don’t make sense. 418 kg of rare earths is equivalent to about 3 MW of power, but the onboard generators’ output is only 80 kW. You don’t need a lot of rare earths for the targeting laser (think grams), and the point of using rare earth motors to guide missiles is that they are compact and lightweight.

The Pentagon’s needs are small compared to global markets, it will just come down to who is willing to pay the most for western-supplied materials.

P.S. Gallium isn’t a rare earth.

anyone who still thinks that the United States has technological superiority in military hardware over Russia and China has not been paying attention. compare their hypersonic missiles to ours–the ones we don’t have after multiple failed tests.

While I won’t underestimate the ability of the US to wreak military destruction upon weaker nations, I welcome information like this that shows how much neo-liberal, de-industrializing policies have hollowed out the real might of the US military. Readers of this analysis might be interested in what Arnaud Bertrand shared recently about China’s newly won independence from US control of helium supplies.

The full article he references is behind a paywall, but his summary is interesting. (I am not sure how to post a link to his substack, but if you are interested you can find it fairly easily.)

The REE-extraction industry in China is heavily polluted; there are lakes nearby which will kill you if you drink from them. Any REE extraction project will need to do this. REE processing will only happen in a Third World country.

There is a Canadian company (Neo Performance Materials) which runs an international, vertically integrated mining->extraction->high-end magnets production chain. They have been around for (I think) 10-20 years. Their extraction and processing was done by a Chinese subsidiary, but a few years ago they read the obvious “tea leaves”, disengaged from their Chinese subsidiary (I think they sold it) and started a new project in Estonia. It is now in operation. NPM, as I mentioned, also makes high-end magnets using these materials. It takes decades to learn how to do this well; every year, you get a little better.

In short, NPM is what “MP Materials” in the US wants to be. REE processing will never happen in the US, and it takes a long time to get good at making high-end magnets.

Note: the magnets we are talking about are so strong and so brittle that you must wear lab glasses when handling them. They can slam together and shatter, sending shrapnel in all directions. There are people with damaged eyes who learned this the hard way.